You work hard to ensure you have a safe workplace. You regularly host safety meetings, follow all OSHA workplace guidelines, and regularly train your team on the best practices for your industry. But, if you aren’t equipping everyone with the right personal protective equipment (PPE) you could be in a risky position.

In fact, health risks associated with protective gear issues are one of the biggest threats faced by the over half a million workers in this business today. Ready to learn why welding protective gear is so vital for the wellbeing of your employees and workers? Let’s dive in.

What You Need to Know About the Health Effects of Welding

Before we can fully discuss the need for quality personal protective equipment for welders, we have to first discuss the various health effects of welding. While the most common ones are associated with the physical aspects of the occupation, there are others spurred by ongoing exposure to toxins.

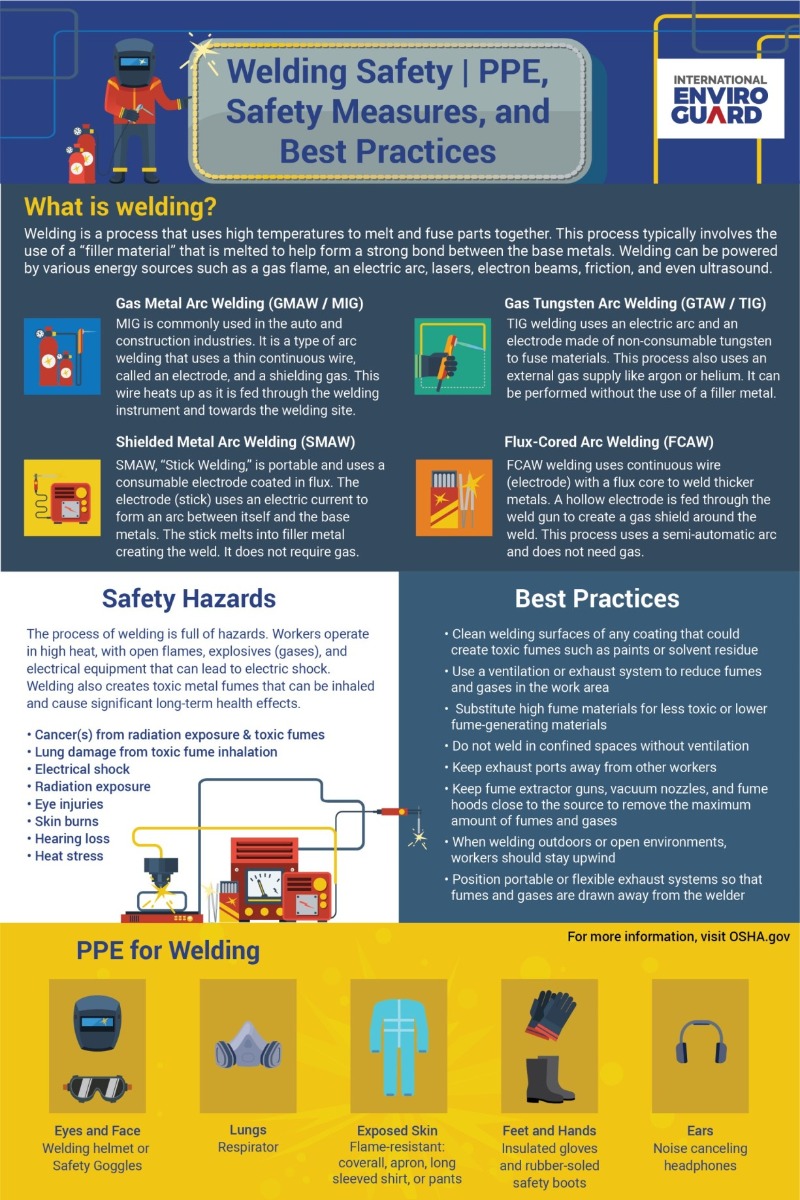

Examples of the most common health effects of welding include:

- Eye injuries and inflammation due to radiation exposure

- Skin burns or cancers due to radiation exposure

- Heat stress or heat stroke due to prolonged exposure to high temperatures

- Hearing loss due to repeat high noise levels within the shop environment

- Lung damage due to inhalation of toxic gasses and welding fumes

- Musculoskeletal injuries associated with the physical demands of lifting equipment and materials

- Health issues or even death associated with electric shock

As you can tell these are very serious, immediate concerns that need to be considered when creating a safe work environment for your employees. Preventing initial injuries should be a top priority, but that isn’t the only potential health risk associated with welding.

What is Welder’s Disease?

In addition to the physical risks associated with this type of occupation, researchers and medical professionals have now discovered another health issue to watch out for. Dubbed “welders disease”, the health ailment is similar to Parkinson’s disease and causes movement problems in the body. The cause? Prolonged exposure to manganese, which is a common ingredient in welding fumes.

Those suffering from the disorder often experience slow movement of the extremities, reduced facial expressions, and even speech difficulties. Workers who performed flux core arc welding over a prolonged period are most likely to develop welders’ disease symptoms, with added exacerbation related to smoking, alcohol consumption, and exposure to common pesticides.

Additional Health Concerns

Of course, you don’t have to be in the welding trade long to understand that this is a physically demanding job. As we continue in an era where the medical community continues to track diseases and symptoms associated with specific types of employment, we are starting to learn that many common diseases are linked with spending multiple decades employed as a welder.

Other illnesses doctors have linked with exposure to toxins while welding include:

- Significant increased risk for all types of cancer, with a specific emphasis on lung, stomach, bladder, kidney, and brain cancers

- Higher than average risk of mesothelioma

- Increased risk of neurological issues not defined by the symptoms of welders’ disease.

- Impaired cognitive function and greater disposition to Alzheimer's disease and pre-senile dementia.

Types of PPE for Welding

Keeping all of the various health risks we’ve mentioned in mind, you can see why purchasing welding protective gear for your employees is so crucial. By taking adequate steps now, you can not only be in compliance with workplace safety regulations, but also ensure the health and wellness of your staff far into the future. And that is likely the most important reason to be concerned.

The most common types of welding protective clothing include respiratory protection, eye protection, face protection, skin protection, hearing protection, and foot protection. Each category involves different guidelines for overall effectiveness as outlined by the safety industry.

Respiratory Protection

There’s no doubt that exposure to the various chemicals, gasses, and vapors associated with welding can cause both short term and long-lasting health issues. While methods to provide proper ventilation within the work environment are always the most crucial, respiratory PPE can provide an additional layer of protection.

The OSHA welding, cutting, and brazing standard 1910.251 fully outlines the type of respiratory protection equipment that should be used and the various hazardous scenarios in which it is required for compliance. Additional information can also be found as part of guideline 1910.252.

Eye Protection

Another critical element of personal protective equipment for welders is eye protection. With sparks, fumes, and heat as a regular part of the everyday landscape in this industry, it is a good idea to ensure all welders always utilize an appropriate form of eye protection.

Those unsure of what level of shade to select should review the OSHA welding, cutting, and brazing standard 1910.252. This guideline includes a descriptive table with the corresponding shade number to the type of welding operation. It is a helpful and detailed resource for you to use as you select the right protective equipment for your workers.

Face Protection

Relating to eye protection is face protection. We’ve chosen to break this out as an individual category, as welding helmets are for more than just eye protection. They also reduce exposure to the skin of the face, nasal cavities, etc.

The two main types of welding helmets on the market are those with passive lenses and those with ADF lenses. Passive lenses feature fixed glass shades or polycarbonate lenses. They’re extremely dark, which means prior to welding they have to be removed and then put back on. In contrast, ADF lenses include a special coating that allows them to adapt to bright light, while still offering easy vision.

Skin Protection

For the health and safety of your workers, ensure all employees wear a double layer of non-flammable clothing while completing all welding operations. This should include coveralls and/or shirts with fire-resistant sleeves, leather gloves, a leather apron, and a fire-resistant skull cap underneath a welding helmet.

Additional steps should also be taken to ensure full compliance on this process. While providing welders with everything necessary for skin protection is a good start, repeated reminders and/or protocols with ramifications should be utilized, too. After all, welders are human and can sometimes forget the reasons why you’re making them wear multiple layers of equipment in such a hot and often uncomfortable environment.

Hearing Protection

Occupational noise exposure concerns are not unique to welding. All businesses operating within the United States must follow OSHA guidelines 1910.95 and remain within permitted decibel levels for various exposure times in hours within a given day.

While the official website for this standard includes a table with the acceptable levels, ensuring your team has the right hearing protection at all times is crucial. By purchasing PPE that not only meets or exceeds this standard, you can help keep your welders safe and prevent overall hearing loss as they age.

Foot Protection

It might sound a little odd to include foot protection as a separate category in this list, but the truth is that it is a critical component to safety. Employee footwear should be both flame-resistant and strong to prevent injuries from dropping heavy objects, sparks, and other potential risks. Anti-slip soles made from heavy rubber are also recommended, as they can reduce the chance of a fall in the workplace.

The best part about this type of welder PPE is that manufacturers have come a long way over the last few years in coming up with quality designs. Today’s shoes for welders are more comfortable and lightweight than ever before, which makes it far easier to work long hours on your feet in extremely hot conditions.

Quality Matters When It Comes to Welding Protective Gear

Now that you know the various types of safety wearables required for welders, it’s time to start looking at the various options available to you. Unfortunately, not all PPE for welding is the same, which makes it more important than ever to choose a quality provider who understands the importance of this type of equipment.

At International Enviroguard, we’re committed to helping businesses ensure safety. That’s why we’re happy to offer a full range of protective equipment options specifically for those in the manufacturing and welding industries.

If you’re just starting your shop or looking to upgrade your PPE, our team is more than happy to answer questions and provide product recommendations. Best of all, we offer competitive pricing designed to ensure you’re able to purchase what you’re looking for all in one place.

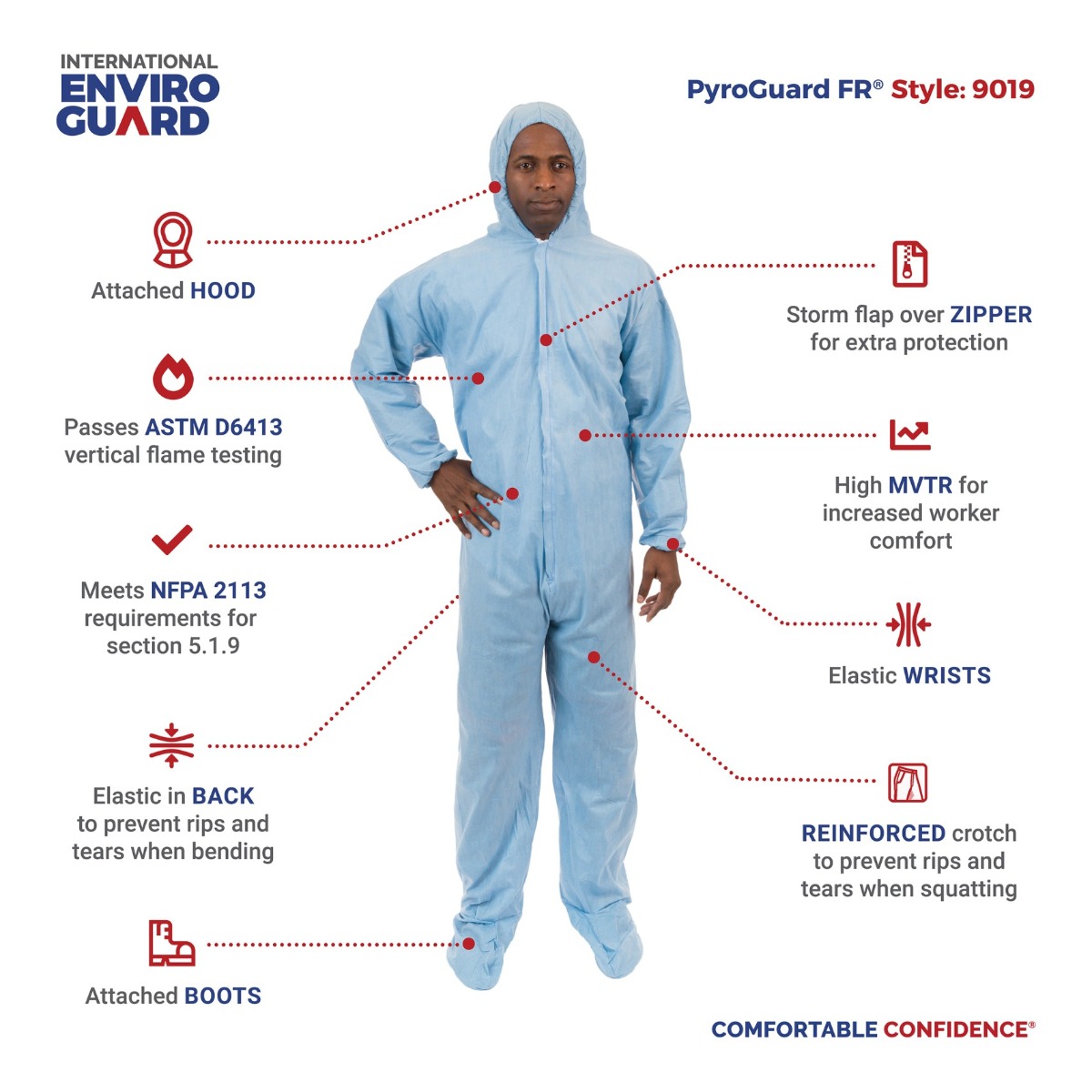

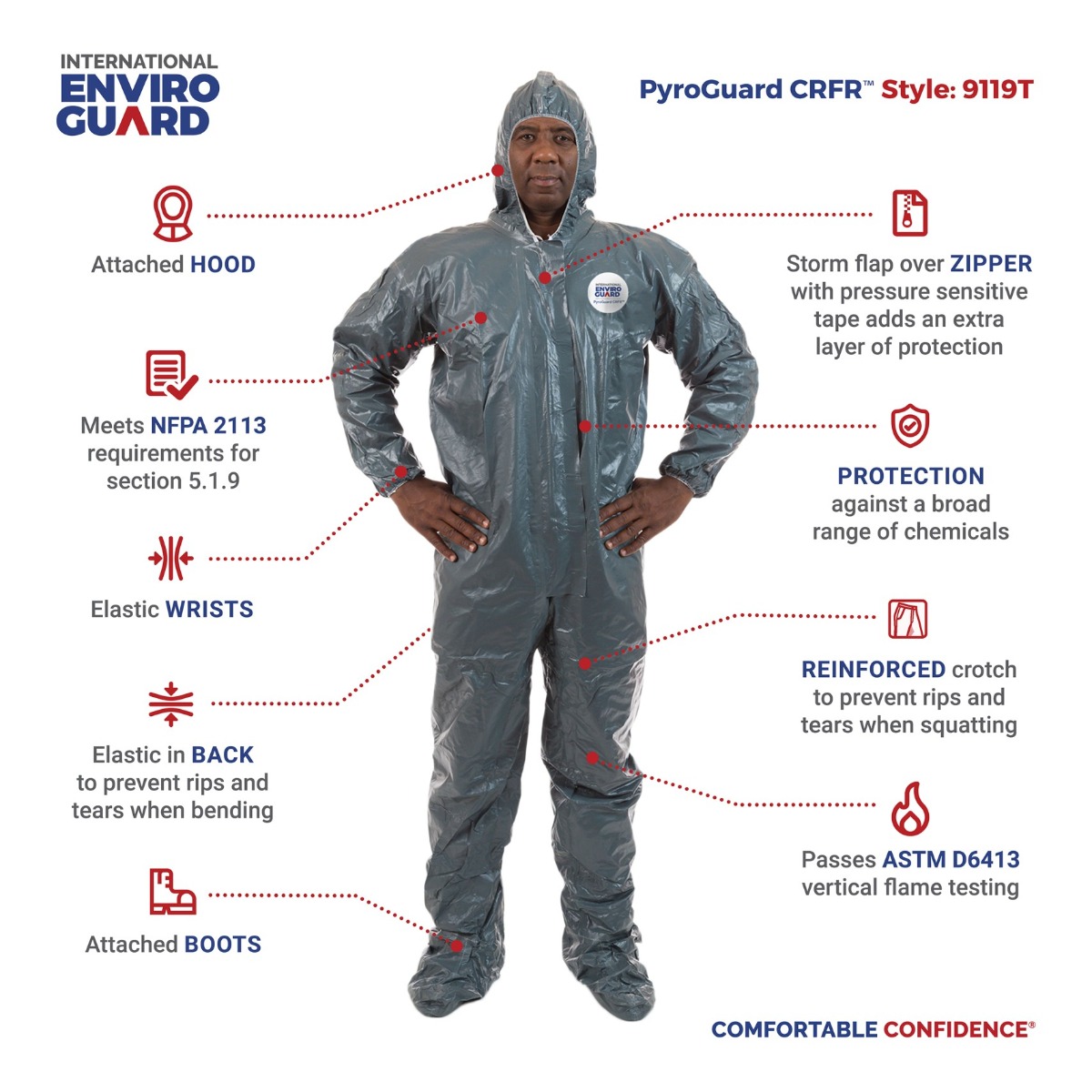

International Enviroguard offers a full line of disposable, flame-retardant coveralls that are in a variety of styles (lightweight, heavyweight) making them ideal for environments where sparks and flames are a risk. Both our PyroGuard FR® and PyroGuard CRFRTM flame-retardant coveralls also protect against dirt, grease, grime, and paint. All coveralls feature a storm flap over the zipper for an added layer of protection as well as an elastic back that stretches with the wearer for enhanced comfort and better tear resistance.

PyroGuard FR® passes ASTM D6413 vertical flame testing and meets NFPA 2113 requirements for section 5.1.9. The breathable, lightweight fabric uses a phosphate-based fire retardant to deprive flames of their fuel source to prevent them from spreading and to prevent molten drips. This coverall line also has a high moisture vapor transmission rate (MVTR) meaning the fabric allows for heat and moisture vapor to escape so wearers stay cooler, especially in hot environments. This product line includes standard FR coveralls, coveralls with an attached hood, as well as coveralls with an attached hood and boots for full body protection. All coveralls have long sleeves and pant legs to protect the arms and legs from sparks and/or flames.

Browse all PyroGuard FR® Coveralls

PyroGuard CRFRTM coveralls provide flash fire protection that meets NFPA 2113 and offer a broad range of chemical protection against a variety of chemicals commonly found in the manufacturing, petrochemical, and welding industries. These coveralls are made of a proprietary bi-laminate fabric that protects against flames and chemicals and also self-extinguishes to prevent flames from spreading or creating molten drips. Seams are taped to help prevent chemicals from seeping through exposed seam holes. This coverall line offers two suits—one with an attached respirator hood, and one with an attached respirator hood and attached boots.

Browse all PyroGuard CRFRTM Coveralls

Wrap Up: Protecting Your Employees from Welding Hazards with PPE

As you can tell, quality welding protective gear is crucial to anyone working in this type of manufacturing environment. The health and safety of your welders is paramount and that starts with ensuring they have the right equipment for their needs. By doing this, you’re minimizing the risk of injury and future medical concerns for the long-term health of your employees.

Not sure where to start with outfitting your team? International Enviroguard is here to help. We offer a wide range of welding protective gear for numerous manufacturing and industrial applications. Please contact us today to learn more.