It's flammable. It's dangerous when inhaled. And it doesn't smell particularly great.

We're talking about hydrogen sulfide—a gas that both occurs naturally in certain environments, and one that is used in a variety of manufacturing processes. But if you're not careful, it also has the potential to make you extremely sick. Exposure can also be fatal.

This post covers what hydrogen sulfide is, what it's used for, and how to stay safe from exposure to this toxic gas.

What is Hydrogen Sulfide?

Hydrogen sulfide, or H2S, is a flammable, toxic gas that typically releases a rotten egg-type smell in low concentrations. Also commonly referred to as swamp gas, sewer gas, or stink damp, hydrogen sulfide is common in industries such as mining, oil and gas refining, tanning, paper processing, and certain types of manufacturing. Because it tends to manifest naturally in many such environments, it's something that safety professionals must account for. This gas is also captured and used in certain manufacturing processes. Regardless of where it forms or how it's utilized, the health effects of exposure to H2S can be significant.

What is Hydrogen Sulfide Used for?

Hydrogen sulfide is primarily used in the creation of certain chemicals. It may also be administered in certain manufacturing processes. And as noted in the previous section, it also forms naturally in the right environments. It tends to be heavier than air, which causes it to literally "sit" in certain environments. If work needs to be carried out in said environments, proper ventilation of the gas is often necessary before work can begin. If ventilation cannot be carried out, it's essential that workers are properly protected with the right PPE.

What Industries Encounter this Substance?

It's worth noting the number of industries that often have to account for and check hydrogen sulfide gas levels as it naturally occurs. Such industries include:

- Mining

- Oil and gas refining

- Paper processing

- Certain types of manufacturing

- Tanning

What are the Health Effects of Exposure?

Hydrogen sulfide has the potential to be a major health threat. For starters, H2S is known to collect in low and enclosed spaces where it forms. Because of how flammable H2S is, when this occurs, so does the potential for explosion. Even exposure at low concentrations can be dire. There's also the potential for individual exposure, which can come with a slew of additional side effects. The next sections outline both the short-term and long-term potential health effects of H2S exposure.

Short-Term Health Effects of H2S Exposure

The most common short-term health effect that most people experience is irritation to the eyes, nose and throat. This is largely because the main routes of exposure to H2S are either via inhalation or through skin or eye contact. Inhalation can also result in headaches, vomiting and dizziness.

If H2S exists in a liquified state and comes into contact with the skin, it's common for individuals to experience a mild frostbite type of sensation. This may eventually lead to burning, blistering and tissue deterioration over time.

Long-Term Health Effects of Exposure to Hydrogen Sulfide

The long-term effects of exposure to H2S can be dire. Contact with the eyes can lead to permanent damage, which may include blindness. Inhalation can lead to life-threatening situations, such as pulmonary edema. Other lung issues include the development of asthma or regularly experiencing shortness of breath, chest tightness, and other respiratory-related issues.

Exposure is also linked to nervous system complications and may cause restlessness and irritability, memory loss, personality changes, and a lack of overall concentration. It may also lead to a loss of smell, notably if individuals have been exposed to high concentrations of the gas.

Common Exposure Routes of H2S

The main exposure routes of H2S in a gaseous state are via inhalation or eye contact. In a liquefied gas state, there's the potential for skin contact, which can result in the frostbite-like symptoms. Luckily, ingestion is not a common exposure method.

What PPE Should I Wear When Working with Hydrogen Sulfide?

Hydrogen sulfide safety is critical. Hence, various H2S safety procedures should be in place in the environments and industries where it may be present. Part of a good H2S safety program involves equipping workers with the right PPE to keep them safe from H2S inhalation and exposure. Here's a look at the protective equipment that workers should be wearing:

- Respirators: Because one of the main avenues of H2S exposure is via inhalation, respiratory protection is essential. And when working in environments with H2S, employers must establish a respiratory protection plan that complies with OSHA standards. But it's not just enough to have respirators on hand for workers. Workers must be properly evaluated and deemed medically fit to wear one. Respirators must also be fit tested on individuals, so they properly worn and not subjecting any workers to accidental exposure. Typically, respirators used in areas where H2S is present should be rated with a concentration of greater than 100 parts per million, or ppm.

- Eye protection: H2S exposure can occur through the eyes as well as inhalation, so eye protection is essential as well. The good news is that a full-face respirator will offer built-in eye protection. But if you're not using a full-face respirator, or the respirator that is being used does not adequately cover the eyes, separate eye protection will be necessary. Chemical safety goggles are the recommended type of eye protection when dealing with H2S.

- Skin protection: What you wear to protect the rest of your body will largely be dependent on the type of environment you're working in, but may include full-body protective suits, aprons, or gloves. Boots should also be worn. Ideally, because of the flammability of H2S, this protective clothing should be fire-resistant.

Hydrogen Sulfide Handling and Storage Recommendations

Aside from PPE, there are various other best practices that workers should follow when working with or in environments where H2S is present. In this section, we'll take a closer look at handling and storage recommendations.

General Safety Measures

It's important that only professionals with specific training on H2S work in environments where it is present. There are numerous safety practices to follow. These include:

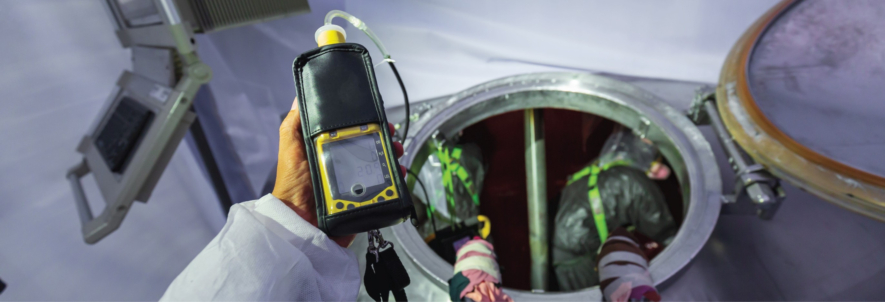

- Test the air with an electric meter before entering an environment or workspace where H2S may be present. If it is, the site should enact fire safety precautions. The site should also take measures to properly ventilate the air and remove the gas from the enclosed space. If the H2S cannot be vented, workers should don the appropriate PPE before entering. Don't rely solely on smell to determine if there's hydrogen sulfide presence in an environment - make sure the air is appropriately tested.

- Any exhaust or ventilation system deployed to remove H2S from an environment should be non-sparking, grounded, and corrosion-resistant. Remember, H2S is a flammable gas.

- Ensure workers are properly trained on the health consequences of H2S exposure, the proper PPE to wear, and emergency action plans should someone be exposed. Smoking should not occur anywhere near a site where H2S may be present.

- In the event of exposure to H2S, the individual should be removed from the environment to a place of fresh air. Once in fresh air, first aid can be performed on the individual as necessary. If the exposure was significant and an adverse reaction is experienced, the individual should seek further medical attention immediately.

Handling and Storage Measures

H2S should always be stored in an environment that is cool and dry. Ideally, this environment is also well-ventilated and out of direct sunlight to avoid any potential for ignition. Even empty containers of hydrogen sulfide can pose a fire threat, so they should be safely stored as well. Cylinders of H2S should be stored upright and moved safely with a hand truck or similar type of appliance.

Exposure to hydrogen sulfide is serious and has the potential to lead to a lengthy list of health complications. In the most severe situation, exposure can lead to death. That's why it's important to take the proper hydrogen sulfide safety measures to eliminate exposure and ensure workers are properly protected in such environments. Proper training and ensuring that workers are wearing the right PPE in these environments is key. Take the steps today to review safety protocols in environments where H2S is present and adjust your policies accordingly to keep everyone safe.