When it comes to hazardous materials on the job, most people picture things like harsh chemicals, flames, and sharp objects. However, fiberglass can be dangerous to one's health, particularly if it gets into your skin. Fiberglass splinters are hard to remove and can do some damage if left untreated.

Because fiberglass is so widely used, many workers in various industries are at risk of fiberglass exposure and splinters. In this article, we're going to provide some background on why fiberglass is hazardous, how it's used, and what you can do to get rid of fiberglass splinters. Here is what you need to know.

What is Fiberglass?

Technically speaking, the name Fiberglass is a product name for home insulation. However, although it is a trademark, the term "fiberglass" is widely used, much like Kleenex, Q-tip, or Dumpster. As the name implies, fiberglass is precisely that - glass fibers. The material is the same you would find in your windows or beverage bottles; only it is much longer and thinner.

Glass is heated until molten, then pushed through an ultra-fine mesh to create tiny filaments. Usually, fiberglass is measured in microns rather than inches or centimeters. These filaments are either used individually (i.e., for insulation) or woven to create patches of material. The length and purity of the glass depend on the specific application. As we'll discuss next, fiberglass is prevalent in many unique industries for various purposes.

There are four primary types of fiberglass, including:

- A-Glass - Patches are very similar to standard windowpanes. A-glass is chemical resistant.

- C-Glass - This version is also called chemical glass due to its resistance, but it's not used in patches like A-glass.

- E-Glass - The E stands for electricity since these fibers are excellent at insulating energy.

- S-Glass - This fiberglass is used for structural purposes, such as molding car bumpers.

How is Fiberglass Used?

There are multiple reasons why fiberglass is a widely used manufacturing material. It's cost-effective, lightweight, corrosion-resistant, and highly durable. Since the filaments are so thin, they are highly flexible, meaning that manufacturers can mold the material into virtually any shape. Here are some common uses for this versatile material:

- Electrical Insulation - Fiberglass is excellent at insulating electricity, even at low thicknesses.

- Anti-Slip Pads and Grating - Fiberglass padding is ideal for chemical plants and slaughterhouses, where various fluids would corrode other, less resilient materials.

- Vehicles - Many automotive parts, including bumpers and doors, are made of S-glass. The military and aerospace industries also use fiberglass pieces.

- Pool Components - Fiberglass doesn't corrode from chlorine and other chemicals and retains its durability.

Overall, any location where water, electricity, or corrosive materials are present, fiberglass can be used because it has natural anti-slip properties, won't dissolve, and insulates well against sparks and other electrical surges.

What are the Health Risks and Symptoms Associated with Fiberglass Exposure?

Although fiberglass is useful and practical for many purposes, it can be harmful. Some common fiberglass dangers include:

- Skin Irritation and Pain

- Eye Irritation and Redness

- Indigestion and Stomach Discomfort

- Nose or Throat Soreness

One of the primary dangers of fiberglass is that the filaments are so small, they can easily penetrate the skin and cause irritation. Even worse, spotting the fiberglass itself is challenging because it is so thin and light. In some cases, workers can accidentally inhale fiberglass dust, which leads to soreness, irritation, and indigestion. Continued exposure to fiberglass dust can lead to chronic health issues like asthma or bronchitis.

Another potential health issue can be contact dermatitis. This term refers to a persistent or painful skin rash. If fiberglass exposure does result in a rash, you may want to see a dermatologist to receive medicated cream to help the redness and itching subside.

There was a time when glass wool (a material similar to fiberglass) was considered a carcinogen. However, in 2001, the International Agency for Research on Cancer downgraded glass wool's status, citing that instances of cancer in factories were not any different or more prevalent than that of the general population. Overall, fiberglass is not inherently dangerous, but workers who don't wear protective equipment are more at risk.

Which Industries are Exposed to Fiberglass?

These days, fiberglass can be found almost everywhere. As mentioned, any area where constant wetness, corrosive materials, or electrical circuits are located can benefit from fiberglass installations. Here are the top industries that are exposed to fiberglass the most.

- Automotive Factories - Since so many auto parts are made of this material, workers handle it all the time.

- Marine and Boat Manufacturing - Like cars, boat shells are almost always made of fiberglass.

- Electronics and Circuitry - Fiberglass components can be found in many circuit boards.

- Pool Manufacturing - Above-ground pools are made of fiberglass, as are many pool-related products, such as steps, liners, and tiles.

- Power and Chemical Plants - Fiberglass insulation is used to protect against electrical surges and rust.

One point to keep in mind is that fiberglass products are safe to touch and handle. Once the filaments are woven and pressed, they won't come loose and get into your skin or eyes. Typically, the danger lies from exposure to fiberglass insulation since it uses filament bundles rather than solid pieces.

Dust can also be an issue if you're cutting or sanding any fiberglass products. For example, if you're trying to toss an old set of pool steps, cutting them into smaller chunks could cause you to breathe in fiberglass particles. If that happens, you'll likely experience an intense coughing fit and some heavy wheezing.

Unfortunately, there is no way to remove fiberglass from your throat or lungs, but eventually, it will push its way through your body. The primary danger is continued exposure, which can lead to long-term illnesses like asthma.

What is the Process for Removing Fiberglass From the Skin?

If you get fiberglass insulation in skin, the affected area will start to itch. As we mentioned, it can be tough to see the filaments since they are so small. In some cases, however, you might be able to see the tip sticking out, making it easier to remove. Here are the two best options for how to remove fiberglass insulation from skin.

- Tape - If you can see the filament, place a piece of tape over it. The fiber will stick to the surface, and when you pull the tape off, the filament should come out with it.

- Washcloth - According to the Department of Health and Human Services, you should wash the affected area with warm water and soap. Doing this loosens the fiberglass, allowing you to wipe it out of the skin with a washcloth.

What Should You NOT Do When Attempting Fiberglass Removal From the Skin? Why?

Although fiberglass filaments will make your skin itch, one of the worst things you can do is scratch the affected area. The reason why scratching is such a bad idea is that it could drive the fibers further into the skin.

You can also tear the filament into smaller pieces, making it impossible to remove. Instead, you'll have to wait until your body pushes the foreign object out itself, which can take hours or days, depending on how far it is beneath the surface.

Which PPE Helps Protect Against Fiberglass?

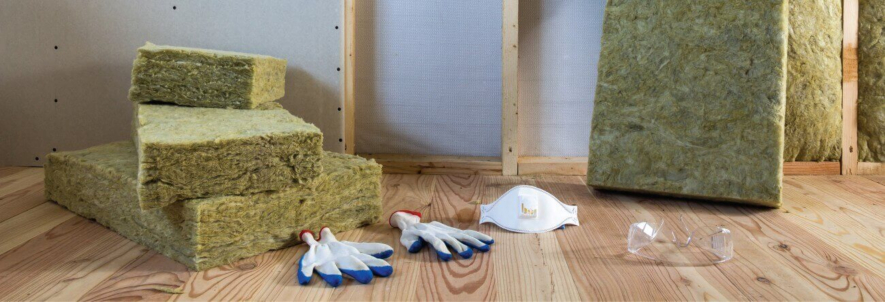

The best way to avoid any health problems is to wear the right protective equipment. Again, compressed fiberglass (like that found in your car's bumper) is safe to touch. However, if you're working around fiberglass insulation or manipulating any fiberglass pieces (i.e., cutting or sanding), you need protection. Here is a comprehensive list of the various PPE you can wear. The amount you should have on-hand depends on the specific application.

- Gloves - While fiberglass filaments can easily embed in your skin, they can't penetrate a pair of thick work gloves.

- Safety Goggles - Filaments on your hand can get into your eye if you rub them. Wearing goggles prevents this accidental transference, keeping you from having to go to an eyewash station. Full goggles are necessary if fiberglass dust is present since the particles can float through the air.

- Face Mask or Respirator - Fiberglass dust can be made of extra-small particles. If you are cutting any fiberglass components, you need a tight seal around your nose and mouth. If you're only touching and handling the filaments, a standard face mask should offer sufficient protection.

- Long Clothing - Your hands aren't the only places where filaments can embed in the skin. Protect your arms and legs by wearing long-sleeve shirts and pants. You may also consider coveralls so that you can keep filaments off your regular clothing.

Whenever working with fiberglass, you want to avoid brushing your hands on your clothing. Instead, it's better to take them off and wash them as soon as possible. Since filaments can get stuck to your clothes, you don't want to create an accidental health hazard at home. This is another reason to wear disposable coveralls.

Protect Your Workers from Fiberglass With International Enviroguard

OSHA regulations state that all employers must always provide sufficient PPE for all employees. Don't risk a worker's comp claim or lost productivity due to fiberglass. Let International Enviroguard equip your worksite with high-quality PPE that is built to last.

Browse our disposable PPE and accessories that can shield workers from fiberglass exposure: