It may come as a surprise, but many mass-produced items pose a risk that requires personal protective equipment (PPE) to be worn during the manufacturing process. For example, a chemical known as Perchlorate is present in dry food packaging. This chemical negatively impacts brain development. Most people do not know that Phthalates are integrated into inflatable toys and common garden hoses. It can increase the danger of heart disease and obesity in children.

The point of these examples is not to instill fear among consumers. Rather, this discussion is designed to identify the wide-reaching sulfuric acid hazards prevalent in the workplace that go into commonly used products. Unless hard-working people can identify health and safety risks, they cannot be mindful of the sulfuric acid PPE requirements necessary to keep them out of harm’s way.

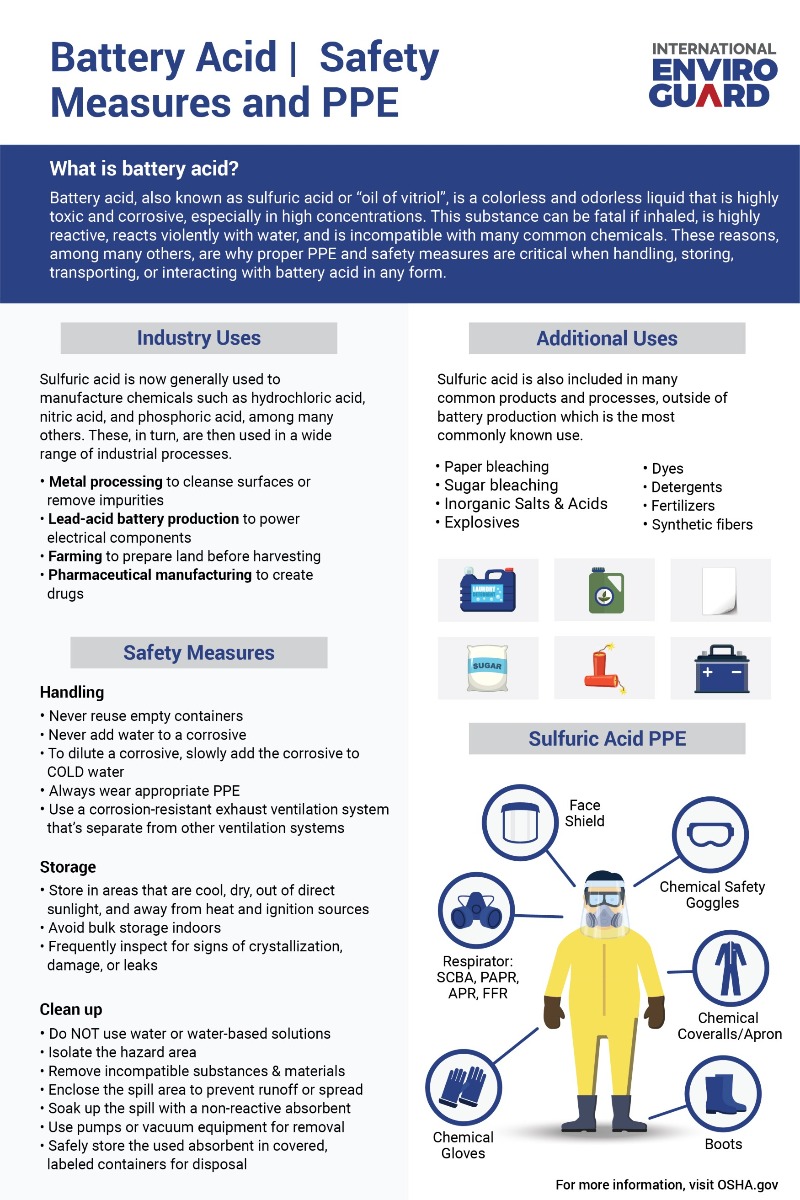

What is Sulfuric Acid?

It’s worth noting that sulfuric acid is not a modern chemical solely used as battery acid, although these terms are interchangeable. Alchemists developed the useful mineral acid, previously called “oil of vitriol,” and employed it for a wide range of uses. Because sulfuric acid can be effectively diluted, it remains a cost-effective asset that has growing applications. Production of sulfuric acid has a market share that reportedly exceeded $10 billion (USD) in 2020 and is expected to top $11.3 billion by 2027.

Persistent sulfuric acid hazards remain obvious during the manufacturing process. However, its inclusion in the products below and others expands the need for sulfuric acid PPE requirements and disposable clothing in the workplace.

- Dyes

- Detergents

- Explosives

- Fertilizers

- Inorganic Salts & Acids

- Metallurgical Processes

- Paper Bleaching

- Petroleum Refining

- Pharmaceuticals

- Steel Manufacturing

- Sugar Bleaching

- Synthetic Fibers

The list of sulfuric acid uses proves increasingly exhaustive as industries discover innovative ways to refine products by leveraging the relatively inexpensive chemical. Its growing use also opens the door to heightened health and safety risks.

Examples of How Sulfuric Acid is Applied in the Workplace

Sulfuric acid is now generally used to manufacture chemicals such as hydrochloric acid, nitric acid, and phosphoric acid, among many others. These, in turn, are then used in a wide range of industrial processes. These rank among the uses that sometimes fly under the radar.

- Metal Processing: Steel manufacturing calls for impurities such as rust to be removed from surfaces. This practice is called “pickling” among steelworkers. Companies typically use sulfuric acid or hydrochloric acid to cleanse surfaces. It’s essential for workers to understand the hydrochloric acid also has sulfuric acid in it.

- Lead-Acid Battery Production: Common car batteries typically use sealed, lead-acid batteries to power electrical components. Sulfuric acid diluted to approximately 33.5 percent is widely used to balance the flow of electrons in the product. Because this remains the most well-known use, battery acid PPE is necessary during production. It’s also essential to wear protective gear when opening, storing, and disposing of acid-based batteries.

- Farm Harvests: It may come as something of a surprise, but potato farmers routinely hire contractors to spray their field before harvesting. The chemical agent used to kill the green tops and stems allows harvesting equipment to sidestep entanglements. Diluted sulfuric acid ranks among the prevalent chemicals used in potato spraying.

- Pharmaceutical Manufacturing: Drugs used in chemotherapy employ sulfuric acid in agents such as alkylating antineoplastic. These and other medications require chemical plant workers to store and handle sulfuric acid in warehouse and production settings.

The sometimes-unknown presence of this dangerous compound poses a significant risk to unsuspecting workers. This holds particularly true among new employees whose experience wouldn’t ordinarily lead them to believe its presence existed. But after weighing the side effects and direct health threats, supervisors and hourly-wage earners should insist on a readily available stock of battery acid PPE.

How Can Sulfuric Acid Exposure Harm Workers?

Sulfuric acid poses a greater threat to health and safety than everyday people typically realize. The most common contact with it stems from checking automobile batteries or examining the green, corrosive deposits on cables. That experience usually includes a harsh chemical smell that warns people against making contact. In a commercial setting, workers may not have the benefit of that telltale odor.

In its base form, sulfuric acid presents as an odorless and colorless liquid fully capable of causing harm. In highly concentrated forms, it has significant corrosive powers. That’s the primary reason sulfuric acid threatens workers' health, safety, and lives in the following ways.

- Skin Contact: This mineral acid goes further than causing chemical burns on human skin. It also has the ability to cause secondary thermal burns due to dehydration. In essence, sulfuric acid remains a dual skin burn threat.

- Eye Contact: Sulfuric acid is not an agent that flushing the eyes with water will necessarily cure. When this powerful chemical splatters into someone’s eyes, they can be rendered permanently blind. Those fortunate enough to keep their sight experience pain, swelling, and redness.

- Ingestion: Inadvertently drinking small amounts of sulfuric acid typically results in burned lips, mouth, and throat, and harms internal organs. Victims usually experience cramping, nausea, vomiting, and diarrhea. Ingestion often results in permanent internal damage and can prove fatal.

- Inhalation: This agent can go airborne when heated or accidentally misted. Prompt symptoms such as irritation of the nose and throat are usually followed by coughing and shortness of breath. Victims of sulfuric acid exposure often suffer permanent lung damage, and inhalation can prove fatal.

Workers who are exposed to even low levels of sulfuric acid over long periods develop red, dry, and cracking skin conditions. Exposure to relatively high levels of airborne particles wears away tooth enamel and results in lung damage. One of the lesser-known facts about sulfuric acid is that it ranks among carcinogens known to cause cancer. Lung and larynx cancer have been tied to long-term exposure. In essence, sulfuric acid should be treated with the heightened protections one would expect in work environments laced with airborne asbestos.

Best Safety Practices When Working with Battery Acid

Although battery acid PPE is a must when handling this inherently dangerous chemical, prudent workplace policies are also necessary. By following stringent guidelines and companies publishing environment-specific policies, heightened awareness and care can be achieved. These are general protocols to consider when working with sulfuric acid.

- Handling: Wear battery acid PPE that includes protective gloves, splash-resistant clothing, protective eyewear, and foot coverings. In the event workers are tasked with opening vats of sulfuric acid or agents it has been blended into, OSHA-rated masks are advised.

- Storage: Supervisors and workers should never store containers of sulfuric acid in direct sunlight. It’s advisable to store this chemical in a cool, dry, and secure area. Safe storage helps avoid it going airborne and minimizes the risk of accidental spills.

- Clean-Up: Before cleaning up sulfuric acid, crews should employ a neutralizing agent. Common baking soda has proven effective in many cases. Once the acid has been rendered neutral, it can be cleaned up with water and appropriate equipment.

Should a sulfuric acid spill occur, non-cleanup personnel should promptly evacuate their area. The danger must be immediately isolated, and no one should approach the risk area without first putting on gear that meets sulfuric acid PPE requirements.

Safety measures may also include applying a suitable absorbent for small spills and leaks. Larger incidents may require certified personnel to dike or enclose the area to prevent it from seeping into other spaces. The best proactive measures of sulfuric cleanups are wearing proper PPE, containment, and mitigation without making contact. In cases where spills may outpace a company’s designated clean-up crew’s capabilities, or a third-party contractor cannot quickly control the threat, local fire departments and hazmat teams should be alerted.

What PPE Should be Worn When Working with Battery Acid?

The sulfuric acid PPE requirements necessary to maximize workplace safety generally go beyond having a set of disposable clothing items handy. It’s crucial for decision-makers to maintain a full inventory of battery acid PPE that fits every person who could be impacted by a spill, splatter, or airborne mist.

This complete inventory should be stored in a suitable space where workers can easily access the disposable clothing they need. International Enviroguard offers disposable clothing that can be deftly accessorized to deliver determined protections against sulfuric acid dangers. Battery acid PPE that meets or exceeds industry standards includes the following.

- ChemSplash® 1 and ChemSplash® 2 Protective Suits: These industry leading product lines deliver reliable protection against skin burns caused by chemical splash and spills. Coveralls and accessories have been rigorously tested to protect against noxious chemicals and come in styles with or without an attached hood and with or without attached boot coverings. All chemical suits come with a storm flap over the zipper to prevent hazardous chemicals from seeping through exposed seams. Taped seams are also available for added protection against chemical splash. Chemical splash aprons and sleeves are also offered to enhance safety and to decrease exposure areas on the body if a coverall is not worn. Whether you need protection against light-duty chemicals, acids, and particulates or from more aggressive chemicals, acids, and caustics, the ChemSplash® product lines are fit for the job.

- Gloves: Protective gloves are a necessity when handling even sealed sulfuric acid containers. A worker’s hands often make first contact with seepage or spilling liquid.

- Face Mask: Routine protection calls for breathable masks to prevent inhalation. Traces of airborne acid can cause cancer or damage the lungs.

- Face Shields: Clean-up crews and people handling open containers of sulfuric acid would be well-served to wear both a breathable mask and face shield.

It’s essential for experienced and new employees to remain vigilant about sulfuric acid safety measures. Along with following safe handling practices, adhering to sulfuric acid PPE requirements could prevent long-term injury, severe health conditions or save lives.

Browse our chemical protective product lines below to learn more about their capabilities and features. If you would like to request a sample or have questions about our products, please click one of the buttons below.

Resources

- https://www.safetyandhealthmagazine.com/articles/11862-battery-acid-hazards

- https://www.ccohs.ca/oshanswers/chemicals/chem_profiles/sulfuric_acid.html

- https://nj.gov/health/eoh/rtkweb/documents/fs/1761.pdf

- https://www.atbatt.com/blog/battery-acid/#:~:text=Battery%20acid%20is%20sulfuric%20acid,levels%20differenciate%20with%20some%20brands.&text=Sulfuric%20acid%2C%20also%20known%20as,formula%20of%20H2SO4%20in%20H2O.

- https://www.health.harvard.edu/blog/common-food-additives-and-chemicals-harmful-to-children-2018072414326

- https://www.cs.mcgill.ca/~rwest/wikispeedia/wpcd/wp/s/Sulfuric_acid.htm

- https://www.britannica.com/science/sulfuric-acid#:~:text=In%20various%20concentrations%20the%20acid,petroleum%20refining%20and%20metallurgical%20processes.

- https://www.worldofchemicals.com/430/chemistry-articles/industrial-applications-of-sulfuric-acid.html

- https://www.msdsonline.com/2014/07/22/sulfuric-acid-safety-tips-sulfuric-acid-msds-information/