Introduction

When selecting chemical protective clothing, one of the most critical considerations is how well the material resists liquid chemical exposure. Standards such as ISO 6530 (previously known as EN 368, and now updated to EN ISO 6530:2005) provide a structured way to test and classify fabrics in terms of their ability to repel and resist penetration by liquid chemicals.

These classifications give users, safety managers, and procurement teams a scientific basis for comparing materials and making informed decisions about protective equipment.

This article explains what ISO 6530 covers, how the testing is performed, and what the penetration and repellency classes mean for workplace safety. We’ll also explore real-world applications, examples, and purchasing considerations to help ensure safer PPE choices.

What is ISO 6530?

ISO 6530 specifies laboratory methods for evaluating protective clothing materials when exposed to liquid chemicals. The standard focuses on three key performance aspects:

- Penetration – how much of a liquid chemical passes completely through the fabric.

- Repellency – how much of the liquid runs off the surface instead of being absorbed.

- Absorption – how much liquid soaks into the fabric itself (though the main classification is based on penetration and repellency).

The standard is particularly important for Type 6 chemical protective clothing, which provides limited protection against light liquid splashes or sprays, rather than full immersion or high-volume exposure.

How the Test is Performed

The ISO 6530 test method is designed to simulate small-scale splashes of hazardous liquids. The process can be summarized in a few key steps:

- Sample Preparation: A flat fabric sample is securely mounted on a test rig at a fixed angle, usually 45°.

- Liquid Application: A measured amount of test liquid (e.g., water, sulfuric acid, sodium hydroxide, or organic solvents) is carefully dropped onto the fabric.

- Collection: The liquid is collected in two ways:

- Run-off liquid is gathered to calculate how much was repelled.

- Absorbent paper placed beneath the fabric sample catches any liquid that penetrates through the fabric.

- Measurement: The amounts of liquid in each collection point are weighed and compared to the original test volume.

This process provides two key values:

- Repellency Index (%) – the proportion of liquid that runs off.

- Penetration Index (%) – the proportion of liquid that passes through the fabric.

What Does It Measure?

The test is not meant to simulate every real-world chemical exposure, but rather to give a controlled measurement of fabric resistance under standardized conditions. Results help indicate whether a garment will offer basic splash protection and how well it holds up against specific challenge chemicals.

It is important to note that ISO 6530 is not a permeation test. Permeation testing (such as ISO 6529) measures how molecules of a liquid or gas pass through a fabric over time. ISO 6530 instead focuses on short-term splash scenarios. Together, these tests provide a more complete view of garment performance.

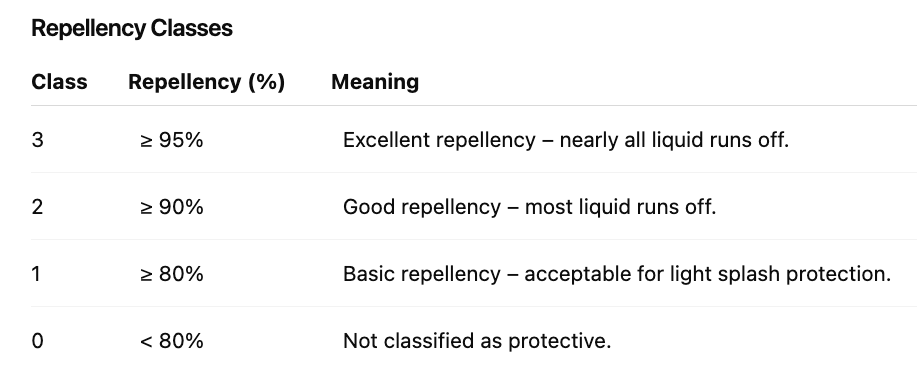

Repellency Index

The repellency index tells us how much of the applied liquid was rejected by the fabric and rolled off instead of soaking in.

- A high repellency percentage means most of the chemical runs off the surface quickly, minimizing contact with the material.

- A low repellency percentage means the fabric tends to hold liquid on its surface or allows it to soak in, which increases the risk of penetration.

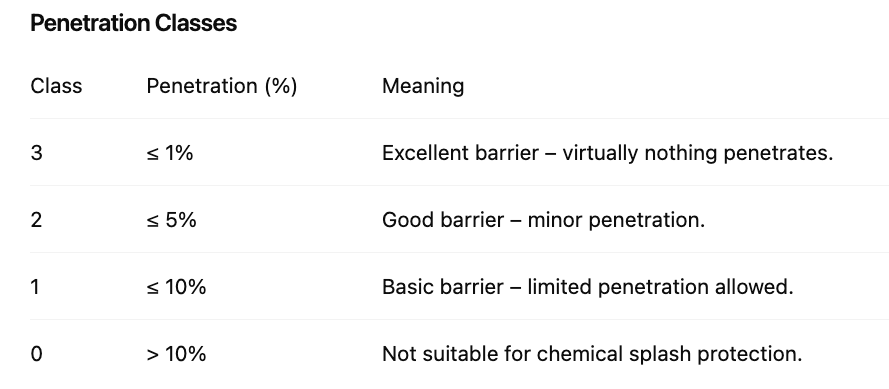

Penetration Index

The penetration index indicates how much liquid gets past the fabric and reaches the layer beneath.

- A low penetration percentage means the material effectively blocks the liquid from passing through the fabric.

- A higher penetration percentage suggests the garment may allow unsafe amounts of liquid contact with the skin or underlying clothing.

Why These Tests Matter for Protective Clothing Safety

The purpose of these classifications is to help users match protective clothing to their specific workplace hazards. Some key points include:

- Chemical-Specific Performance: A material may score high (Class 3) against one chemical but perform poorly (Class 1) against another. Always check results for the actual substances workers are exposed to.

- Limited Protection: ISO 6530 classifications reflect splash resistance only. They do not guarantee protection against full immersion, pressurized sprays, or long-term contact.

- Real-World Scenarios: In industries such as agriculture, pharmaceuticals, and chemical processing, splashes are common. Workers rely on garments with proven repellency and penetration ratings to minimize risk.

- Purchasing Decisions: Safety managers should look at both repellency and penetration scores when evaluating garments. High repellency with poor penetration resistance (or vice versa) may leave workers vulnerable.

Industry Examples of ISO 6530 in Action

- Agriculture and Pesticide Application

Farm workers who mix and spray pesticides often face exposure to dilute chemical mixtures. A fabric with high repellency ensures most of the spray runs off, while a low penetration index keeps harmful residues from contacting the skin or underlying clothing.

In this case, garments tested under ISO 6530 offer reassurance that workers won’t be absorbing unsafe amounts through clothing.

- Oil and Gas Industry

Maintenance staff working with cleaning chemicals or hydraulic fluids may encounter unexpected splashes. Fabrics rated at Class 3 repellency and penetration provide extra protection against corrosive acids or caustic solutions commonly used in refinery processes. - Pharmaceuticals and Laboratories

Lab technicians frequently work with solvents and reagents. A protective coverall that achieves strong repellency ensures spills don’t cling to the fabric, while low penetration scores prevent contact with the wearer’s skin—vital in sterile environments where contamination control is critical. - Emergency Response and Hazmat

First responders attending to chemical spills need rapid protection. While ISO 6530 garments are not designed for full hazmat immersion, they offer critical splash resistance in early response stages, allowing for safe evacuation and decontamination.

Practical Example

Suppose a protective coverall is tested against sulfuric acid (H₂SO₄). If the fabric achieves:

- Repellency Class 3 (≥95%) → almost all of the liquid runs off.

- Penetration Class 3 (≤1%) → nearly no liquid passes through.

This combination demonstrates excellent splash protection against sulfuric acid. On the other hand, the same fabric may score only Class 1 repellency when tested with an organic solvent like o-xylene, showing that its performance varies depending on the chemical.

This highlights why users should never assume that high performance against one chemical guarantees similar protection across all hazards.

Beyond the Numbers: Other Considerations in PPE Selection

While ISO 6530 scores provide valuable guidance, they are only part of the selection process. Safety professionals should also consider:

- Comfort and Breathability: Garments must balance chemical resistance with wearability. Overly rigid or non-breathable suits can cause heat stress and reduce compliance.

- Durability: Repeated flexing, abrasion, and wear can reduce protective properties over time.

- Compatibility with Other PPE: Suits should integrate well with gloves, boots, and respirators without leaving gaps.

- Chemical Permeation Testing: For environments with prolonged chemical exposure, permeation resistance (ISO 6529) is just as critical as splash protection.

Conclusion

Understanding ISO 6530 penetration and repellency classes is essential for anyone involved in selecting protective clothing for chemical hazards. These tests provide a standardized, reliable way to compare fabrics and assess their suitability for splash protection.

- Repellency (%) indicates how much chemical is shed (not absorbed) by the fabric surface.

- Penetration (%) reveals how much liquid makes it through the material.

- Together, they determine whether a garment can be trusted for limited chemical splash scenarios.

While ISO 6530 does not replace permeation or breakthrough testing, it serves as a valuable first line of assessment. By considering both penetration and repellency scores for the chemicals of concern, safety professionals can choose garments that strike the right balance between protection, comfort, and compliance.

In industries from agriculture to oil and gas, these scores are not just numbers—they translate into real-world protection for workers handling hazardous substances. A clear understanding of ISO 6530 empowers decision-makers to invest in PPE that truly safeguards people on the job.