It's a metal alloy that you'll find in a variety of products, ranging from sporting goods to automotive parts. It's known for its hardness, durability, resistance to temperature fluctuations, and its ability to withstand wear and tear. But in the manufacturing environment, it can pose health consequences for those that come into contact with its powder or dust byproduct.

We're talking about tungsten carbide, a common alloy. You may be wearing it on your finger or around your neck in the form of jewelry. The vehicle that you drive every day may have a bevy of parts crafted from it under its hood. Even the ski poles that you use when hitting the slopes may be made from the material. Yes, tungsten carbide is popular - but it's also potentially hazardous in the manufacturing stages. In this post, we'll take a closer look at what you and your workers need to know about tungsten carbide exposure, how to stay safe from exposure and much more.

What is Tungsten Carbide?

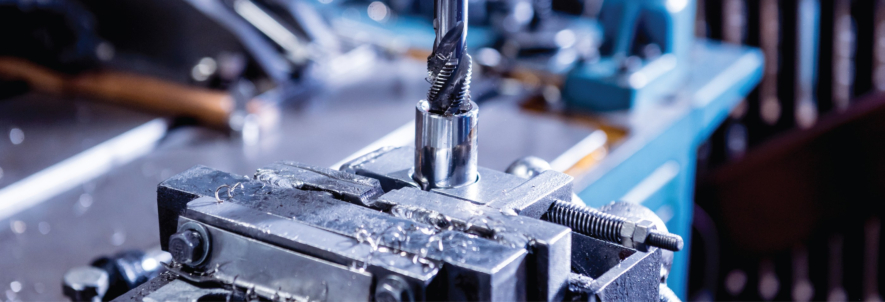

Like we noted above, tungsten carbide is a metal alloy that's commonly used in manufacturing. In its solid form, there are no known health hazards. However, when tungsten carbide is grinded, polished, sharpened, welded, or sprayed, it can become a gray dust or powder-like substance that can be easily inhaled or come into contact with a worker's skin or eyes. This is where tungsten carbide can present some short- and long-term health hazards.

Tungsten Carbide Uses

Tungsten carbide is a preferred metal alloy for several reasons. As noted above, it's hard, wear and tear resistant, and it can also withstand high temperatures. For this reason, it's often used to manufacture a variety of parts, including everything from ski poles to automotive applications. Golf clubs, drill bits, saw blades, and jewelry are other products that are commonly made from tungsten carbide.

Industries that Use Tungsten Carbide

As you can tell from its potential applications above, tungsten carbide is used throughout a variety of industries, from sporting goods to medical to mining to jewelry and other commercial products. The metal alloy is a top choice due to its durability and resistance to wear and tear. However, it's not without its potential hazards.

How are Workers Exposed to Tungsten Carbide?

However, while the machine shop floor in a manufacturing environment is perhaps the most common area where tungsten carbide exposure takes place, keep in mind that many drill bits and other tools are often made with the alloy, so there's also the potential for exposure to take place during select activities in home workshops and hobby garages.

Health Effects: Is Tungsten Carbide Toxic?

Tungsten carbide exposure can present both short- and long-term health effects, especially if the metal alloy also contains nickel and chromium, which it often does. Even just a small level of exposure can have significant health consequences.

Some short-term health effects include a skin allergy, skin burns, or eye irritation. If a skin allergy occurs, even low future exposure could cause additional irritation, such as a rash or itching. Other short-term issues from exposure may include gastrointestinal issues.

More dire health effects involve the regular inhalation of tungsten carbide dust or powder. When inhaled via the nose or mouth, it can cause irritation. It may also lead to wheezing, coughing, and shortness of breath. Repeated exposure and regular inhalation can lead to permanent lung issues, such as scarring or permanent respiratory issues.

Finally, in abnormal conditions, tungsten carbide can even present a fire hazard. If quantity and particle size become too significant in an environment, it could present the ideal conditions for ignition. Again, these situations are rare and can largely be mitigated with proper exhaust and ventilation.

Protective Clothing for Tungsten Carbide (and Other PPE)

The good news about environments where workers regularly come into contact with tungsten carbide is that there are measures that can keep everyone safe and help prevent both short- and long-term health effects.

Tungsten carbide presents a health hazard when it's inhaled or comes into contact with the skin or eyes. For this reason, protective glasses, gloves, a respirator, and a full-body protective suit are often mandated in areas where this dust is common.

In addition, there are a variety of mitigation measures that should also be implemented to complement worker PPE. While respirators may be able to be substituted for proper exhaust and ventilation practices in the work environment, it's better to be safe than sorry. Make sure any respirator is approved to guard against dust and mist particles and that it's properly fit tested.

Safety Best Practices When Dealing with Tungsten Carbide

In addition to wearing the right PPE in environments where workers may be exposed to tungsten carbide dust or powder, there are a variety of other safety measures that should be implemented. Here's a closer look:

- Proper ventilation: Ventilation is key to removing any harmful dust or particles from the workplace environment and can be part of an overall plan to keep workers safe from exposure.

- Follow safety best practices: Even when wearing respirators, full body protective suits, gloves and goggles, exposure may still occur. Make sure that your workforce is able to recognize exposure symptoms quickly and can take action immediately. Eye wash stations should be on site for rinsing the eyes if eye exposure occurs. A shower should also be on site in the event of skin exposure. And if the substance is inhaled, workers should be immediately removed from the site to a place of fresh air. In the event of exposure, further medical testing may be necessary to monitor short- and long-term health consequences. Lung function tests, regular chest X-rays and/or consultation with an allergist or skin specialist may be necessary.

- Follow proper hygiene practices: While this may seem obvious, no worker should smoke, eat, or drink anything in any area where tungsten carbide dust or powder may be present. Additionally, it's always a good idea that workers properly and thoroughly wash their hands prior to eating to avoid possible ingestion.

- Practice proper cleanup: Environments where tungsten carbide exists should never be cleaned with dry sweeping. HEPA vacuums should be administered for cleanup purposes in said environments and the area may also benefit from being wetted / misted so that any airborne dust or powder falls to the floor for easier cleanup.

- Ensure PPE is worn and discarded properly: Wearing the right PPE is important in workplace environments where tungsten carbide is present. Make sure that full body suits are properly disposed of and that any clothing that comes into contact with tungsten carbide is removed and properly laundered. While implementing proper exhaust and ventilation practices is important, respirators should be fit tested, and cartridges should be changed often to ensure they continue to function at their best.

As you can see, while tungsten carbide has a variety of benefits in end-use applications and is a common byproduct in manufacturing environments, the metal alloy is not without its potential hazards. It's important to fully understand these risks to ensure you're keeping your workers as safe and protected as possible. From protective clothing for tungsten carbide to ensuring that there's adequate exhaust and ventilation in manufacturing environments, take steps now to prevent workers from experiencing short- and long-term health effects due to tungsten carbide.