Also known as additive manufacturing, 3D printing has rapidly gained traction in the manufacturing industry. This innovative technology allows producers to create products using a combination of inexpensive materials and highly accessible equipment.

While the popularity of 3D printing has grown, many 3D printing health hazards are just starting to gain recognition. For the protection of all workers involved in 3D printing, it is critical that organizations get familiar with the unique health hazards involved and how to properly combat those risks with the use of proper practices and personal protective equipment (PPE).

The 3D Printing Processes

The 3D printer is an advanced piece of equipment that can utilize user inputs on a computer and filaments or printing materials to create dimensional objects layer by layer. Essentially, the printer stacks multiple layers of a raw material until the three-dimensional shape has been created.

The majority of 3D printers use what is referred to as feedstock, which is a plasticized filament. The threaded filament gets fed through a heating element where it is liquefied, and then the fluid plastic is released through a controlled nozzle to create an object.

Numerous types of thermoplastics may be used as feedstock, including Acrylonitrile Butadiene Styrene (ABS), nylon, and Polylactic Acid (PLA). However, some 3D printers also rely on ultraviolet light to cure a piece, lasers for shaping a piece, and even metal powders to create a piece.

Industries That Use 3D Printing

One of the biggest benefits of 3D printing is that the process offers the ability for product engineers to quickly and inexpensively create parts and products in-house. Therefore, initially, 3D printers were primarily put to use in engineering processes.

Engineers could use a 3D printer to build a prototype from the ground up with little cost involved. However, now this tech-based form of printing has grown to be a common process in everyday manufacturing and production processes. Some companies now use numerous 3D printers in their operations on a daily basis.

You don't have to look far to find 3D printing technology in action. To date, 3D printers have made their way into numerous settings, including medical laboratories, automotive parts manufacturers, electronics manufacturers, and even the aerospace industry.

The ways in which these industries rely on 3D printing can vary drastically from one to the next. For example, some medical practices are using 3D printers to create custom, built-to-fit prosthetics for patients. Likewise, some automotive parts manufacturers use 3D printers to create plastic parts for automobiles.

Potential Hazards of 3D Printing

3D printing hazards can include breathing in harmful chemicals or compounds, skin exposure to harmful chemicals or solvents, and the risk of fire and explosion. Some printers operate at extremely high temperatures, which could also mean the user is at risk of getting burned.

3D printing hazards vary depending on what type of equipment, materials, and setup are used. For instance, some printers use fine powders that can cause skin or respiratory hazards, while others may use ABS filaments that produce hazardous emissions upon heating. Two primary threats come along with exposure to ultrafine particles (UFPs) and volatile organic compounds (VOCs).

UFPs are referred to as nanoparticles because they are anywhere from 1 and 100 nanometers in size. These particles are so small, they can be inhaled, travel through the bloodstream, and even make their way into bodily organs. UFP exposure has been linked to:

- Cardiovascular disease

- Respiratory infection

- Lung cancer

- Chronic obstructive pulmonary disease (COPD)

VOCs can vaporize even at room temperature. These organic chemicals can then saturate the surrounding environment's air and pose health hazards. Some materials commonly used in 3D printing processes, such as nylon, PLA, and ABS produce particularly concerning VOCs like butanol and styrene.

Some VOCs are thought to be active carcinogens (cancer-causing agents). However, VOCs can have a variety of other

damaging health effects, including:

- Central nervous system damage

- Irritation of the throat, nasal passages, and eyes

- Loss of general coordination

- Headaches

- Nausea

- Skin irritation

Some 3D printers also use chemical solutions to dissolve unnecessary support pieces that are printed during the creation of a 3D piece. These solutions are corrosive, so they pose risks to the eyes and skin such as blindness or chemical burns.

How Organizations Can Protect Workers from 3D Printing Hazards

The National Institute for Occupational Safety and Health (NIOSH) has rapidly taken initiatives to help organizations protect their workers while using 3D-printing equipment.

Only trained professionals should operate 3D printing equipment.

3D printing may not be the most complicated task, but only trained employees or authorized individuals should have access to the equipment. Untrained or inexperienced workers using the equipment can experience unnecessary exposure to hazards.

Place 3D printing equipment in the proper location.

3D printers should be in isolated enclosures equipped with ventilation to control emissions. If you do not have an isolated enclosure for printing equipment, select a room or location that has high airflow, operable windows, and exhaust to the outdoors.

Opt for 3D-printing materials and equipment with lower emissions.

Printing equipment should be purchased from reputable manufacturers who have created the unit with emissions and safety in mind. A standard has been developed that shows a printer has been designed to reduce emissions.

Look for those that meet the ANSI/CAN/UL 2904 Compliance Standard. Likewise, the filaments used should be carefully chosen. As noted above, some filaments create higher emissions, and some create more toxic emissions.

Reduce time workers are in proximity to printing equipment.

Although watching a 3D printer in action is interesting, employees should not spend any more time near the operational 3D printer than necessary. Some organizations set up alternative cameras or other mechanisms to oversee the printer without an employee having to be nearby.

Train employees on 3D printing hazards.

Employees must know and understand the risks associated with 3D printers. There are many useful resources to help ensure proper training for employees. For example, the NIOSH offers informational posters on 3D printing with metal powders and 3D printing with filaments.

3D Printing PPE to Protect Workers

PPE for 3D printing can be the employee's first line of defense against the many hazards they can face when operating or working near 3D printing equipment.

Therefore, make sure every employee has the proper PPE , understands its importance, and knows how to properly don it.

Fit-Tested Respirators

General dust masks are not designed to block out the particulate matter that's often released during 3D printing processes. Instead, workers need commercial respirators that are NIOSH-approved for protection against both VOCs and UFPs. All respirators should be fit-tested to ensure proper functionality.

Neoprene or Nitrile Gloves

Wearing gloves while working with the feedstock, handling heated pieces, or interacting with solvent chemicals will prevent workers from sustaining injuries on their hands and forearms. All uncured materials coming out of the printer should also be handled with protective gloves.

Splashproof Eye Protection

Wearing gloves while working with the feedstock, handling heated pieces, or interacting with solvent chemicals will prevent workers from sustaining injuries on their hands and forearms. All uncured materials coming out of the printer should also be handled with protective gloves.

Splashproof Eye Protection

To protect the eyes from small particulate matter and potential chemical splashes, employees should always wear protective eyewear while using 3D printing equipment. Consider protective goggles over basic safety glasses because these PPE pieces can block out exposure to UFPs and VOCs by sealing off the eyes.

Coveralls: Flame-Retardant, Chemical-Resistant, or Fine Particulate Protection

3D printing can involve working with hazardous chemicals, powders (particulates), and even pose the risk of flames or explosions. It’s important to identify which hazards are present throughout your 3D printing process to provide the proper PPE for workers.

When working with ultrafine particles and volatile organic compounds, particulate protection is needed. Body Filter 95+® disposable coveralls and garments are breathable and designed to filter out 95%-99% of 0.3-micron particles—similar to an N95 respirator.

Browse all Body Filter 95+® coveralls and disposable clothing

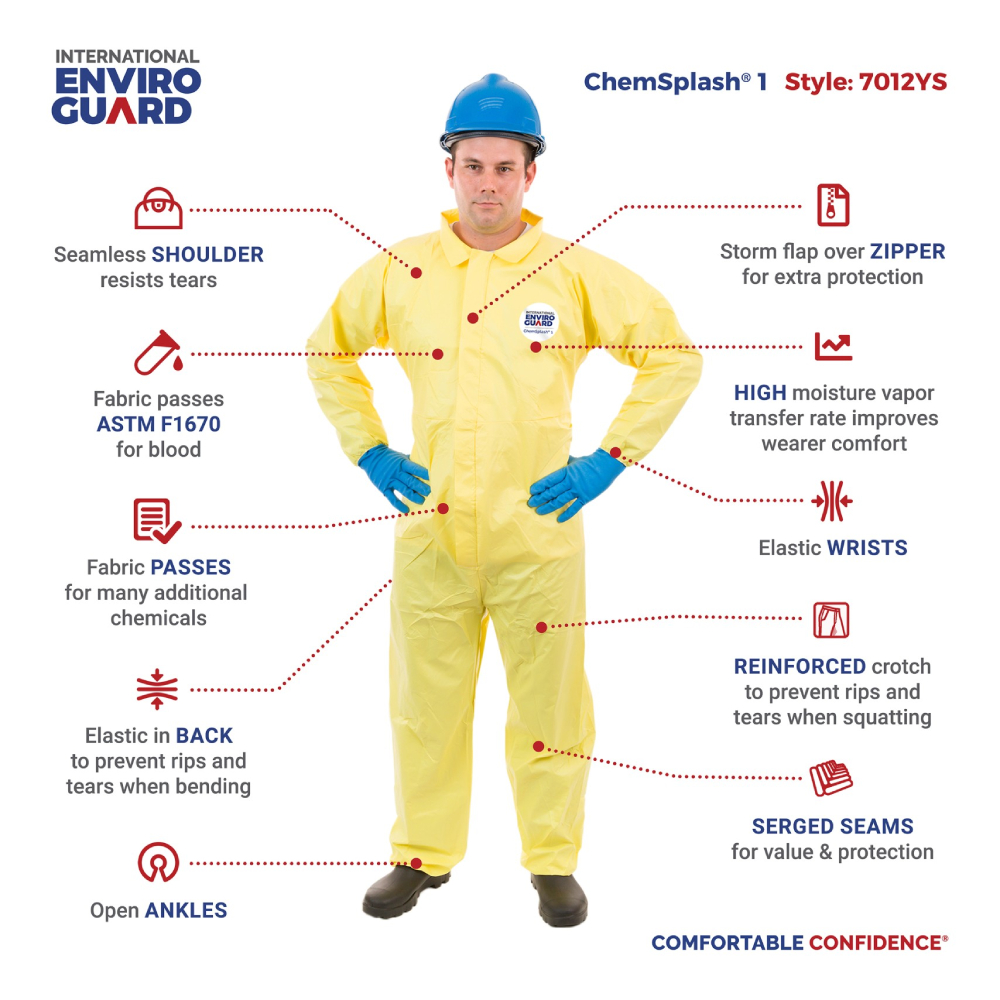

If corrosive chemical solutions are used in your 3D printing process, chemical-resistant coveralls are necessary to protect against chemical burns and chemical splash. ChemSplash® 1 coveralls, splash aprons, and sleeves protect against light chemical splash and less hazardous chemicals. This line includes styles with taped seams for added protection against liquid chemicals that can seep through exposed seams.

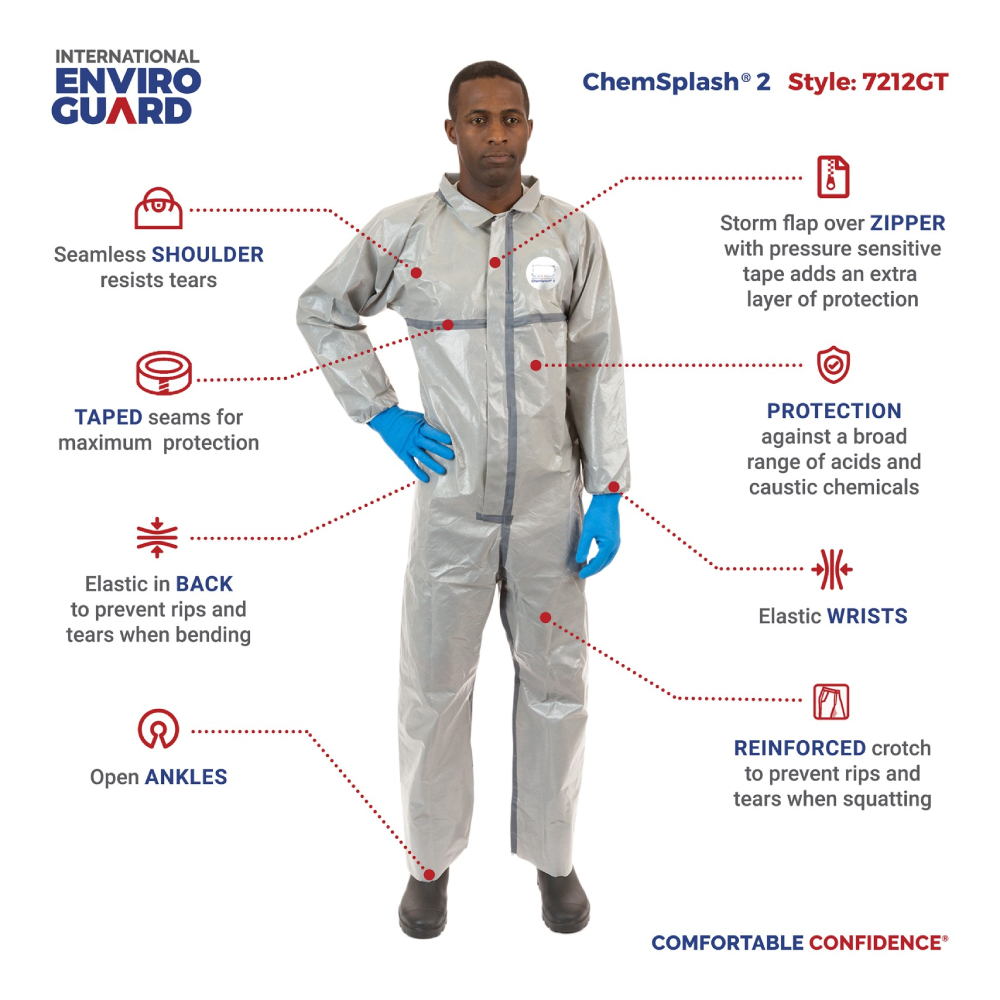

For protection against more aggressive acids, chemicals, and caustics, ChemSplash® 2 coveralls offer the safety you need in more hazardous environments.

Browse all ChemSplash® chemical protective clothing

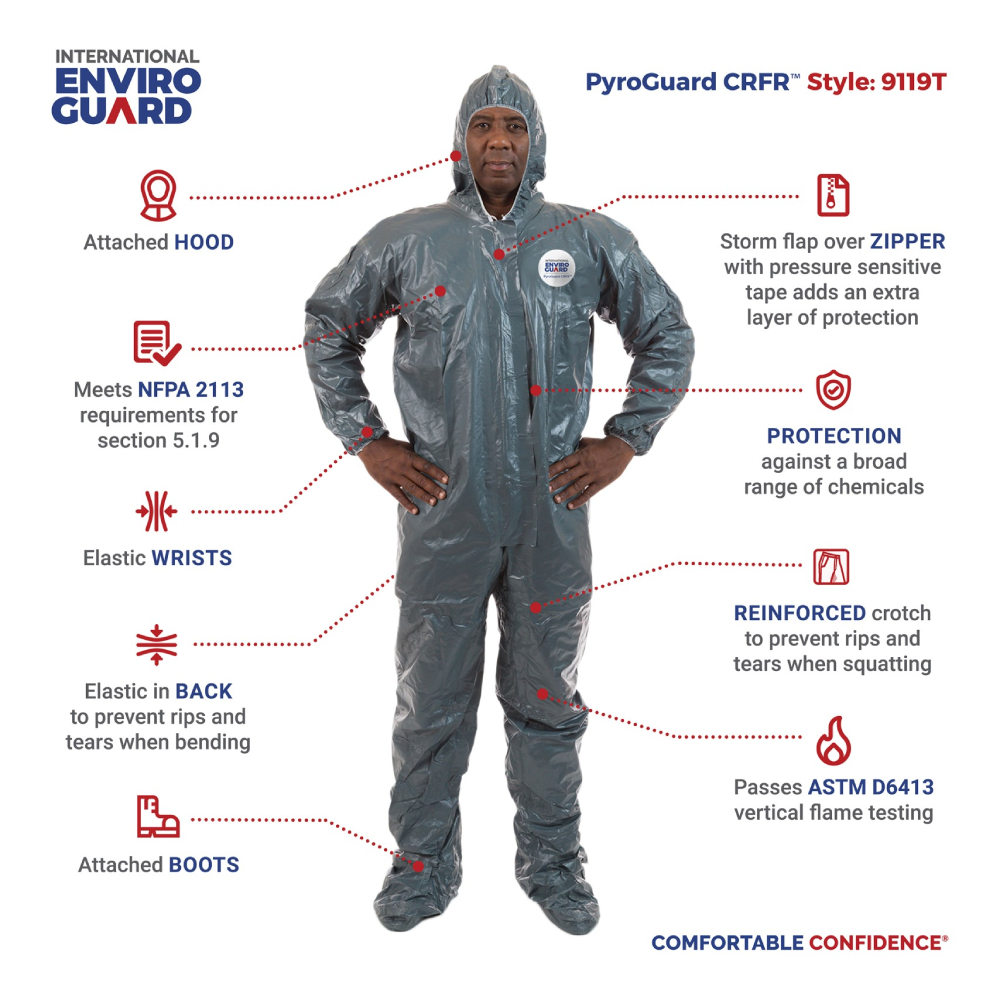

If your 3D printer uses volatile chemical compounds that can ignite and pose a fire or explosion hazard, consider fire-retardant coveralls. Better yet, chemical and fire-retardant coveralls provide protection against both flames and chemicals such as PyroGuard CRFRTM.

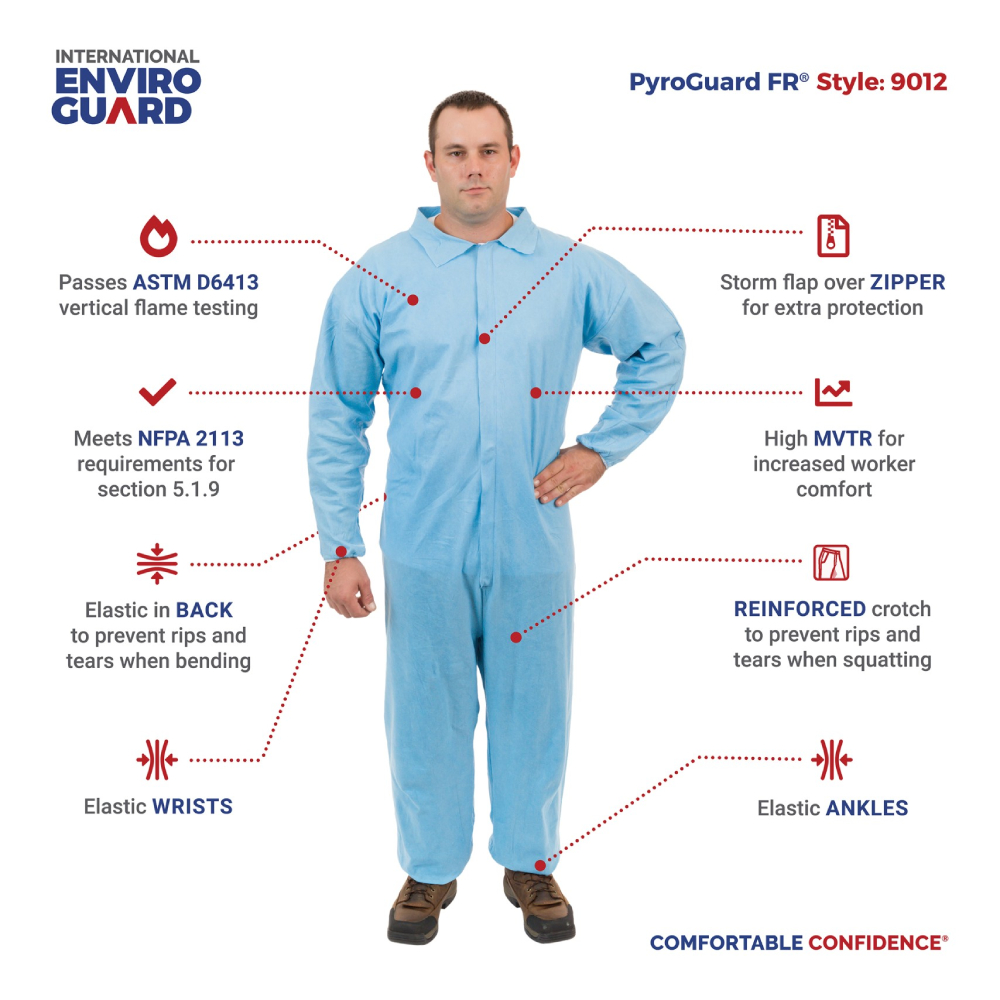

PyroGuard FR® coveralls are flame retardant and pass ASTM D6413 vertical flame testing as well as NFPA 2113 requirements for section 5.1.9. Our PyroGuard CRFMTM increases protection levels by safeguarding against a broad range of chemicals as well as being flame-retardant.

Browse all PyroGuard® coveralls

Safety and 3D Printing

By 2026, the 3D printing market is slated to reach 51.77 billion dollars. As more industries take advantage of this innovative form of production, more attention must be given to health hazards that can be involved.

While 3D printing seems relatively safe, a deeper look proves that compounds, chemicals, and materials used and emitted during printing are hazardous. From ensuring proper safety training to becoming more familiar with which equipment and materials pose the most risk, there are numerous paths to providing adequate protection.