Setting the Stage: Why Dust Protection Isn’t Just About Filtration

When you think of hazardous dust and safety apparel, you might immediately focus on how well the fabric filters out particles. But in many real-world situations, that’s only part of the story.

Dust particles float and move with air; they don’t passively settle like liquids. So even the most efficient filtering fabric can fail you—if the clothing design allows air (and dust) to be drawn in through seams, zippers, or other gaps. The root of this vulnerability is what experts call the Bellows Effect.

What Is the Bellows Effect?

Imagine you're wearing a coverall of non-breathable material (for instance, flash-spun polyethylene). The material doesn’t allow much air to move through it. When you move—walking, bending, reaching, climbing—a portion of the air trapped inside the suit must move somewhere.

But because the fabric blocks airflow, that air is forced through any available openings: seam holes, zipper tracks, cuff openings, collar gaps—just like how bellows (blacksmith’s tool) push in air when compressed and draw air in when expanded.

In short:

- Low air-permeability fabrics ≈ air can’t escape through the fabric.

- Movements of the body create changes in internal air pressure.

- Those pressure changes force air out (when compressed) and in (when expanded) through weak spots (non-sealed seams, zippers, cuff, collar).

- Dust and other particles in the surrounding air is carried with these airflow currents into the interior of the garment.

So, you end up with active ingress of particles—not by them pushing through the fabric, but riding the airflow in through gaps.

By contrast, a garment that lets air permeate through the fabric will relieve many of those pressure differences. The air can move through the fabric rather than being forced through seams or openings. That reduces how much air and particles is pulled in through those weaker paths.

Why It’s Not Enough to Look at Filtration Efficiency Alone

You’ll often see two features listed on fabrics:

- Particle filtration efficiency: how well particles are blocked if they try to pass directly through the material.

- Air permeability: how easily air flows through the material (i.e. breathability).

A fabric with super high filtration but almost zero air permeability can look great on paper—but in use, thanks to the Bellows Effect, it can underperform because the fabric’s inability to let air through forces air and dust through the less-ideal entry points.

A more breathable fabric might filter less perfectly, but because it avoids large internal pressure swings, it may let in fewer particles in total under realistic working/movement conditions.

Testing the Bellows Effect: Whole Garment Inward Leakage (Type 5)

To move from theory to practice, there’s a standard test called the Type 5 whole-garment inward leakage test for protective clothing against hazardous dry particles. Below we describe how this test works:

- Garments go into a cabin/chamber filled with fine dust.

- Wearers perform defined movements: standing still, walking on a treadmill, squatting.

- Inside the garment, probes measure particle concentration (e.g. at knee, back, chest). Another probe outside gives the ambient “challenge” count.

- By comparing inside vs outside, you get Total Inward Leakage (TIL) expressed as a percentage of outside concentration. Lower TIL = better protection.

This test lets you see how many particles penetrate not through the fabric directly, but via ingress through weak points (seams, zippers, gaps) exacerbated by movement (i.e. by the bellows effect).

Real-World Findings: Breathable vs Non-Breathable Garments

Let’s compare two otherwise identical garments in a testing scenario:

- Coverall one — made from a breathable SMS fabric

- Coverall two — made from a non-breathable microporous film laminate

Testing scenario highlights:

- Although the microporous coverall had better particle filtration efficiency (i.e. its fabric resists more particles in a lab filtration test), its total inward leakage was higher (worse) in many cases. For example, average TIL was ~6.2% for vs ~3.14% for the SMS coverall in tests where neither had the zipper taped.

- The situation worsened during more strenuous movements like squatting. With such movement, the non-breathable microporous garment saw much greater leakage relative to the breathable SMS one. In fact, in some tests, leakage was more than double.

- Interestingly, simply taping up the zipper flap on the non-breathable microporous garment reduced its inward leakage dramatically (from ~6.2% down to ~0.27% in one test). This shows how much the zipper is a weak spot for air and particle ingress.

Implications for Personal Protective Clothing: What to Look For

Given what the Bellows Effect tells us, here's how to apply that knowledge when selecting, using, or evaluating protective clothing for dusty or high particulate environments.

- Choose fabrics with balanced filtration + breathability

- Don’t assume non-breathable = better protection. It may filter well but suffer from high inward leakage under motion.

- Breathable fabrics (like SMS or SMMS) may give slightly lower filtration on lab tests but outperform non-breathable ones in whole-garment wear scenarios due to less induced airflow through seams/gaps.

- Seal weak spots

- Zippers are major points of failure. If using non-breathable suits, tape the zipper flap carefully to stop air from being drawn in around the zip teeth.

- Sealed seams, taped seam joints, and overlaps at the interfaces with other PPE (gloves, boots, respirators) are very important.

- Account for movement

- Most test reports show that more strenuous movements increase inward leakage sharply — squatting, bending, reaching.

- If the job involves lots of movement, pick gear that performs well under motion, not just in static filtration lab tests.

- Look carefully at reported leakage results

- Some manufacturers publish very low Total Inward Leakage (TIL) numbers, but those might assume that the zipper flap is taped, or other mitigation steps are in place. Always check the conditions of the test.

- Sometimes the instructions or fine print will reveal that the low leakage only applies under certain configuration steps (zip flap taped, seams sealed).

- Use realistic testing & standards

- Standard tests like EN Type 5 provide a benchmark. But also consider what your real working conditions are: ambient dust concentration; how much movement; temperature; PPE fit, etc.

- If you deal with highly toxic dusts, even small ingress may be unsafe, so you may need more protective (possibly fully sealed) suits.

Why “Good” Dust Protection is More Than Material Specs

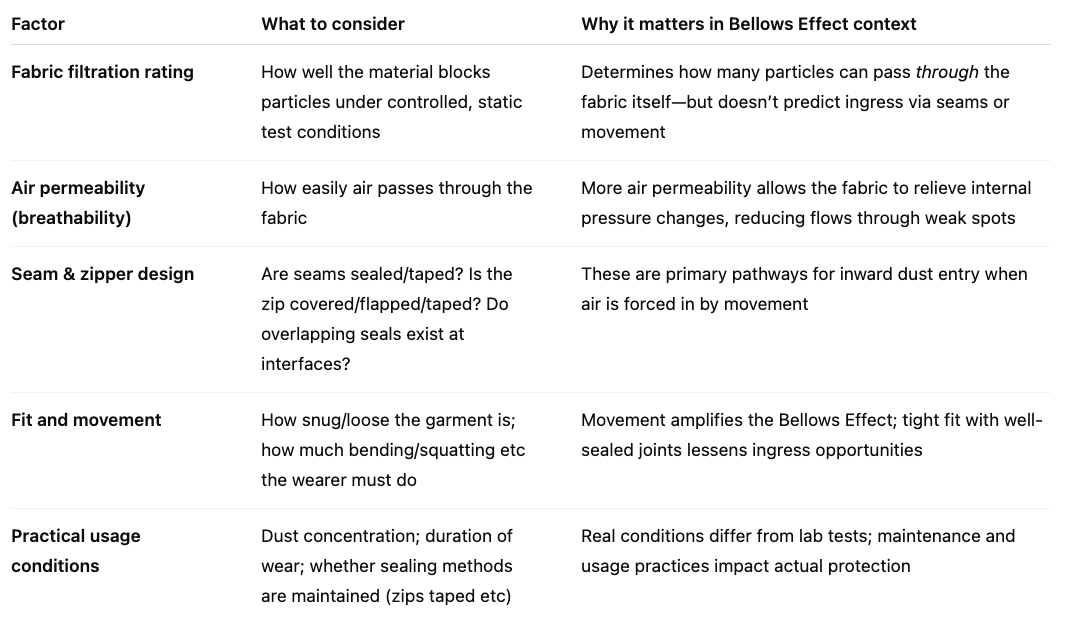

Because of the Bellows Effect, the “best” protective garment is not always the one with the highest nominal filtration rating. Here’s a conceptual summary of what to balance:

The Bellows Effect in Your PPE Policy

Here are some tips you might want to build into your safety / PPE program:

- Train wearers not just in wearing correct garments, but also sealing them properly—taping zippers, closing cuffs, overlapping other PPE interfaces.

- When selecting coveralls or dust suits, ask for whole-garment inward leakage test results under movement. Compare breathable vs non-breathable models under those conditions.

- Monitor and replace PPE that has lost seal integrity—worn or fraying seams, damaged zippers etc. Over time, these weak points degrade.

- For tasks involving heavy movement or high dust loads, lean toward suits that reduce the Bellows Effect i.e. breathable fabric, sealed openings.

Closing Thoughts

The Bellows Effect shows that air movement induced by your own body’s movement can be as significant a pathway for dust ingress as microscopic defects in fabric. In other words, even when the fabric is “perfect”, the garment is susceptible if it does not manage airflow holistically—through material choice, seam/zip design, and sealing.

Understanding this helps you choose and maintain protective clothing that actually works under real conditions—not just in lab specs. If you’re involved in safety procurement, industrial hygiene, or PPE oversight, the Bellows Effect needs to be part of the conversation.