On September 4, 2025, OSHA unveiled its updated regulatory agenda, reordering its standards-setting priorities and making clear which areas will receive heightened attention. Several previously anticipated proposals have been removed, others delayed, while certain emerging worker hazards have been elevated.

These changes come as part of broader shifts in administration policy, regulatory philosophy, enforcement focus, and emerging workplace risks.

Below is a dive into what is driving OSHA’s new priorities, which policies are being sidelined or are in flux, the forces driving these decisions, and the implications for employers and worker safety.

What’s Driving OSHA’s Shifting Priorities

Several factors have combined to push new topics to the top of OSHA’s regulatory agenda:

- Deregulation directives from executive orders: The current administration has issued orders aimed at trimming or removing rules deemed obsolete, redundant, or overly burdensome. For example, OSHA has cited Executive Order 14192, “Unleashing Prosperity through Deregulation,” as justification for withdrawing some proposals.

- Public health and safety emerging risks: Heat-related illnesses, properly sized protective gear, chemical exposure, and exposures to respirable silica are increasingly seen as urgent risks, amplified by changing climate, worker demographics, and heightened public attention when preventable deaths or injuries occur. OSHA is showing increasing interest in rules that address those risks.

- Data-driven enforcement: OSHA is relying more on data (injury/illness rates, hazardous exposure data) to prioritize inspections and rulemaking. Better injury/illness reporting (e.g. via OSHA Form 300A), improved databases, and trending metrics allow OSHA to target inspections more precisely. Programs like Site-Specific Targeting (SST) inspections reflect OSHA’s effort to prioritize workplaces with high or worsening rates of injury, illness, or noncompliance.

- Legal and political environment: OSHA’s regulatory agenda responds to court rulings, stakeholder pressure, and legislative signals. Some proposed rules are being dropped or deferred due to concerns about economic impact, compliance cost, or technical feasibility. Also, stakeholder feedback from trade groups, industry associations, and unions seems to play a key role in deciding what to retain.

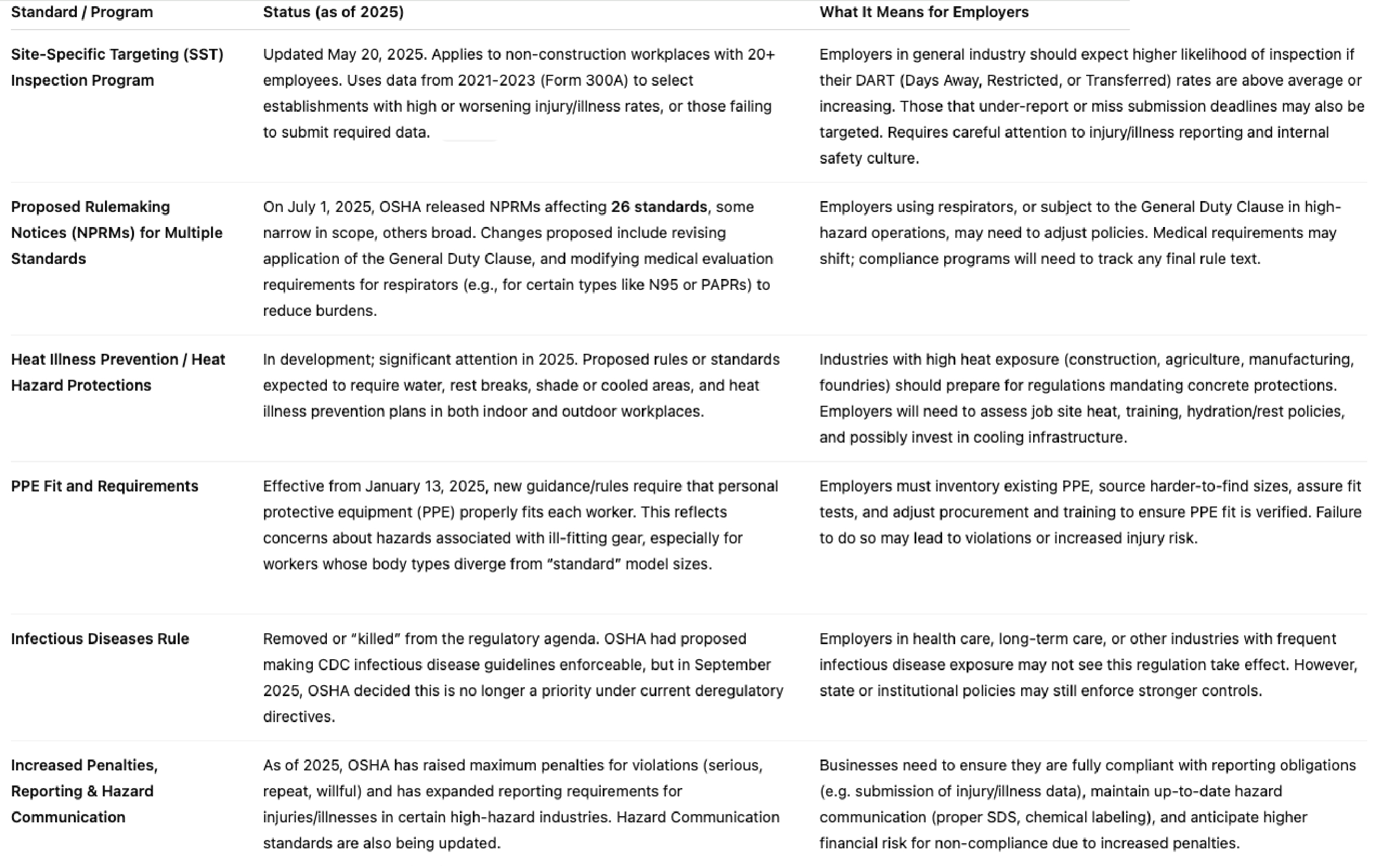

OSHA’s Priorities: What’s on the Table + What’s Being Dropped

Here are some of the main OSHA standards, proposals, and enforcement programs that are rising in priority, along with those that are being de-prioritized or removed.

What This Means in Practice & Impact Across Industries

- Manufacturing, Construction, General Industry — many updates (heat illness, SST, PPE fit) hit these sectors hardest. For example, manufacturers with many employees will be under more scrutiny for injury trends. Construction firms will face tighter PPE fit requirements and possible heat illness rules.

- Smaller Employers — resource constraints may make compliance harder. Investing in new equipment, PPE, monitoring systems, or cooling infrastructure will cost money. Smaller companies may need to plan budgets, adapt in phases, or access consultation services.

- Compliance Costs vs Long-Term Savings — there will be upfront costs (training, new equipment or policy updates), but benefits may include fewer injuries and illnesses, lower insurance costs, and avoidance of penalties. Good recordkeeping and culture improvement may reduce injuries and costs over time.

Why Some Prior Proposals Are Dropped

- Some rulemakings have been withdrawn or paused because they were judged to no longer align with current priorities under executive policy (e.g. deregulation). The infectious disease rule is a major example.

- OSHA also seems to be refining its tasks to focus on enforcement via data-driven inspection programs rather than broad-based rulemaking in some areas.

Policies Being Dropped or Delayed

Some OSHA proposals that had been expected are now being pulled back or removed entirely.

- Infectious Disease Rule: A proposal to make CDC infectious disease guidelines enforceable as OSHA regulations has been withdrawn. OSHA has said this is no longer a priority under current regulatory direction.

- Blood Lead Level Medical Removal Proposal: No longer on the standards agenda. This proposal would have lowered thresholds for removing workers from exposure when blood lead levels reach certain levels. Its removal has raised concerns among public health and worker safety organizations.

- Other Long-Term Rules Still Pending: Workplace violence prevention in health care/social work, updates to Process Safety Management, and silica medical removal protections are categorized as “long-term actions” — meaning they are not active near-term priorities.

What This Means for Employers

OSHA’s reshuffling of priorities has several implications:

- Employers in high-heat environments (e.g. construction, agriculture, manufacturing) should be ready for more formal heat protection rules; even before they become law, many are already being enforced informally or via local/state agencies.

- Industries with hazardous equipment (forklifts/trucks, power presses, tower work) should review their safety programs and ensure up-to-date training, machine guarding, and maintenance.

- Respirator users should monitor upcoming changes and begin preparing for updated medical evaluation, fit testing, and usage rules.

- Employers should watch for increasing enforcement around walking surfaces, slips/trips/falls, lockout/tagout—these are perennial hazards, and OSHA is revisiting them with new vigor.

- While some proposals are gone or delayed (like infectious disease or blood lead medical removal), many worker health advocates see their removal as posing a risk: delays in protections mean continued worker exposure.

Key Takeaways & What Employers Should Watch

- Watch your injury and illness metrics — DART rates and other trends matter more than ever under the updated SST inspection program. DART rate stands for Days Away, Restricted, Or Transferred. It refers to workers that cannot perform any job duties for at least one full day, workers returning to work but with limitations due to injury or illness (reduced hours, modified duties), or a job transfer in which a worker must move to a different role due to their injury or illness. Non-reporting, under-reporting, and increased DART rates can draw inspection.

- Prepare for heat stress and PPE fit regulation — even if final rules are not published, early compliance (training, infrastructure) helps avoid surprises and penalties.

- Stay alert to NPRMs and proposed changes to respirator requirements and general duty obligations — these could change day-to-day compliance requirements significantly.

- Invest in recordkeeping and reporting compliance — Form 300A submissions, OSHA log accuracy, timely data, and submissions are vital.

- Budget for increased penalty exposure — non-compliance isn’t just dangerous; it’s becoming more expensive.

Conclusion

OSHA’s 2025 priorities reflect a sharper focus on measurable, data-driven enforcement, worker protections related to environmental or emerging hazards (heat, PPE fit, chemical exposure) and trimming back less-active proposals.

OSHA is shifting from broad “one-size-fits-all” rulemaking toward targeted enforcement based on data and emerging risks. Deregulation of older rules won’t reduce compliance pressure — inspections, penalties, and documentation demands are intensifying.

For employers, this means that compliance isn’t optional — early preparation, strong safety programs, accurate reporting, and attentiveness to proposed rules will reduce risk and ensure operational continuity. OSHA's shifting regulatory agenda is setting the stage for a more enforcement-oriented safety landscape.

Sources:

“Improving and Eliminating Regulations: Permissible Lamps in Underground Coal Mines.” Federal Register, 1 July 2025, www.federalregister.gov/documents/2025/07/01/2025-11618/improving-and-eliminating-regulations-permissible-lamps-in-underground-coal-mines.

“OSHA Announces New Standards Priorities.” Industrial Safety & Hygiene News (ISHN), 4 Sept. 2025, www.ishn.com/articles/114914-osha-announces-new-standards-priorities.

“OSHA Issues Updated Guidance on Site-Specific Targeting Inspections.” Littler Mendelson P.C., 20 May 2025, www.littler.com/news-analysis/asap/osha-issues-updated-guidance-site-specific-targeting-inspections.

“OSHA Regulatory Agenda, Strategy, and Emphasis Programs: Setting Up Your Year for Success.” U.S. Compliance, 2025, www.uscompliance.com/blog/oshas-regulatory-agenda-strategy-and-emphasis-programs-setting-up-your-year-for-success.

“OSHA Updates: What Employers Need to Know.” Medcor, 2025, medcor.com/safety/osha-updates-what-employers-need-to-know.

“Site-Specific Targeting Inspection Program.” Occupational Safety and Health Administration, U.S. Department of Labor, 20 May 2025, www.osha.gov/news/newsreleases/osha-national-news-release/20250520.

“Workplace Regulation Changes in 2025.” Unico Group, 2025, unicogroup.com/workplace-regulation-changes-in-2025.

“OSHA’s 2025 Regulatory Changes.” CSM Group Insights, 2025, www.csmgroup.com/insights/navigating-oshas-2025-regulatory-changes.