Driven by technological advancements and changing demographics, personal protective clothing innovations continue to evolve and meet worker safety needs. The pandemic radically changed mainstream perceptions about health hazards and how to guard against airborne contagions.

The accompanying personal protective clothing trends left an indelible mark on an industry committed to workplace safety. With the health emergency largely behind us, the latest PPE innovations bring next-generation advancements to disposable personal protective clothing and equipment to reduce work-related ailments and injuries today and in the future.

Technology Integrated into Protective Gear

Personal protective clothing manufacturers have been hard at work reviewing the latest technologies and finding creative ways to use them for the betterment of worker safety. To say keeping pace with the leaps and bounds software engineers continue to make has been a difficult task. But leaders in the safety garment and gear space are revolutionizing the future of workplace protections by using the following.

Augmented Reality

Augmented reality made a splash in the gaming industry. Youngsters and the young at heart adorned headsets that changed their perceptions of the space in front of them. Games such as Pokémon Go onboarded what techies call “AR” to enhance the player experience. While AR games may be entertaining, leveraging the technology to advance worker safety remains serious business.

In terms of protective clothing innovations, the strategic use of AR can help workers maximize the safety benefits of PPE. For example, AR displays can show everyday people how to adorn clothing and gear properly. It can also provide critical information about hazards and dangerous landscapes.

Companies that invest in AR and other personal protective clothing trends can leverage them to improve worker training, increase efficiency, and reduce callouts due to work-related illnesses and injuries.

Smart PPE

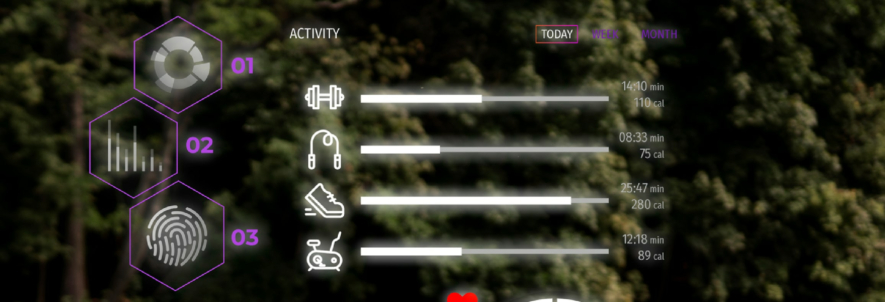

Also known as smart wearable systems, smart PPE provides digital connectivity to laptops, desktops, and other hand-held devices in real time. Smart technologies are being introduced to wide-reaching types of personal protective clothing to monitor the health of workers.

Wearable devices, sometimes called “wearables” in the health and fitness industries, rank among the latest PPE innovations. Custom-embedded into the linings of coveralls, headgear, and breathable masks, they collect critical data. These are examples of familiar wearables.

- Activity Trackers

- FitBits

- Smart Watches

These monitoring systems are particularly useful when first responders, HazMat crews, and others are tasked with handling jobs in sometimes hostile environments. Searing heat and frigid temperatures add significant risk. Smart PPE allows a supervisor to pull people out of harm’s way when their health is at stake.

But there’s another level of smart PPE that employers would be well-served to also consider. There are sensors that can be installed into protective gear that search for imminent threats such as gas leaks, chemical agents, high temperatures, and unusual noises. A safety vest with high-tech sensors can relay the information to a safety supervisor in real time. Many utilize standard Bluetooth connectivity to provide early warnings.

Health Status Sensors

Like smart PPE, health status sensors are also designed to improve workplace safety. One of the sometimes-overlooked ways that personal protective clothing leads to poor outcomes involves improperly fitting inventories. Health status sensors can identify uncomfortably fitting coveralls, pants, hoodies, and breathable masks, among others. This allows safety managers, as well as manufacturers, to make adjustments and alterations.

Other health status sensors can be integrated into wearables that indicate a worker’s proximity to imminent dangers. Many can transmit a team member’s precise location, even in a remote area. Knowledge gives safety managers and boots-on-the-ground workers the information they need to make informed decisions about risks.

Use of Alternative Materials

Outdated PPE made from standard foams often lacked flexibility. When products created based on a designer’s “best guess” didn’t quite fit properly, solutions included thickening or thinning the protective materials. That hit-or-miss approach frequently restricted worker movement, putting people at greater risk of hard-impact falls and ripping or tearing of the garments. Today, protective clothing innovations involve data-driven assessments.

Digital information is gathered to help PPE engineers make strategic decisions on alternative materials such as the following:

Nanofibers

Integrating nanofibers ranks among the more forward-thinking protective clothing innovations. These tiny fibers have the bandwidth to hinder the movement of hazardous elements and pathogens. That’s why industry-leading personal protective clothing manufacturers have already begun using them in breathable masks, disposable protective gowns, pants, and coveralls, among others.

The use of nanofibers is also part of the personal protective clothing trends to produce lightweight and breathable products that safeguard against splatters, heat, and hazardous items while remaining comfortable. This delivers worker comfort over an entire shift. It’s also a cost-effective investment because companies can resume standard daily lunch and coffee breaks.

Biodegradable & Recycled Materials

Personal protective clothing trends are starting to align with the world’s environmental sustainability concerns. Restaurants and grocery stores are fast cutting back on the use of plastic straws, bags, and materials that do not easily decompose.

Although using biodegradable and recyclable materials was once a bridge too far for the safety garment industry, the latest PPE innovations have adapted. Manufacturers are starting to replace materials with eco-friendly options without compromising the structural integrity needed to protect workers.

3D Printed Materials

The rise of 3D printing has not been lost on the PPE manufacturing sector. Thought leaders in the disposable protective clothing space quickly identified its ability to customize products. With comfort, agility, and breathability driving enhanced worker safety, savvy PPE makers are not shy about leaning on 3D-printed materials.

Rising Importance of PPE Designed to Fit Women

One-size-fits-all notions about personal protective clothing belong in the industry’s rearview. The increase in female workforce participation in traditionally male occupations continues to swell. According to the Bureau of Labor Statistics, 1.2 million women were employed in the construction sector in 2020.

Upwards of 30 percent of the manufacturing workforce are women, and industries such as warehousing and trucking continue to push for a more gender-diverse employee pool. There’s no escaping the fact that gender barriers are disappearing, and protective clothing producers must account for physical differences. And, no, the idea of wearing a men’s protective suit one size smaller won’t cut it.

Women in the workplace require and deserve safety garments that fit appropriately. Comfort, agility, and breathability are foundational elements regardless of gender. Those are reasons why seemingly minor waist, chest, glove, collar, and hip sizes are being addressed by forward-thinking disposable safety clothing makers. The construction industry alone is expected to add upwards of 400,000 jobs by 2030, and a growing percentage will need protective clothing designed specifically for women.

Heat Monitoring and Cooling PPE

The National Institute for Occupational Safety and Health (NIOSH) conducted a study regarding cooling PPE in 2016. The organization recommended PPE that helped cool workers in hot and humid conditions. This is particularly applicable to employees who are required to wear long sleeves, ankle-length pants, and arc-flash and fire-resistant (AFR) clothing.

Whether disposable personal protective clothing is worn to deter biting insects during the hot summer months or scalding splatters, subpar garments create physical and mental stress. The very safety measures being used to prevent illnesses and injuries can result in severe health incidents such as heat stroke. That’s why NIOSH advocates for the following solutions.

- Water-Cooled Garments

- Air-Cooled Garments

- Cooling Vests

- Wetted Overgarments

- Water-Cooled Caps

- Long Water-Cooled Undergarments

The PPE industry has also developed high-tech personal cooling units that can lower temperatures. And air-cooled garments rank among the latest PPE innovations that are making a difference. Others include sweat stickers to monitor for excessive sodium loss that could put workers at risk. Ice vests are among the personal protective clothing trends companies that ask employees to carry out duties in searing conditions are buying into.

The advancements in personal protective clothing and safety gear provide employers with a rare opportunity to onboard the latest PPE innovations. Investing in top-tier products typically results in fewer workplace illnesses, injuries, and tragedies.