Safety and regulatory overview for powder coating processes

Powder coating helps protect surfaces, such as metal, from corrosion and also offers a more pristine finish. This process is often used as an alternative to spray paint, however, the powders used in the process present health and safety hazards in their uncured state. The majority of metals can be powder coated; however, if heated to high enough temperatures, other materials such as plastic, glass, wood, and composites can also be powder coated.

As useful as powder coating is, the process is full of many hazards which is why it's always important to have PPE or Personal Protection Equipment available that can keep you safe.

Health Hazards in the Powder Coating Process

Powder coating products and materials are classified as substances that are hazardous to health because they are respirable (breathable) dusts. The dust is very fine and cannot always be seen, so it can be absorbed deep into the lungs.

The majority of powders can result in health effects with significant exposure. Common problems include skin irritation (dermatitis), sensitization of the skin, respiratory irritation, and occupational asthma.

These complications typically result from:

- Powders directly contacting the skin

- Inhalation of the powders

Some powder pigments and curing/hardening agents are particularly toxic. It’s critical to read the safety data sheet (SDS) for each powder coating and be more cautious of highly toxic ingredients such as those listed below:

- TMA (tri-mellitic anhydride)

- TGIC (triglycidyl isocyanurate)

- Lead chromate-based pigments

Other risks include:

- Injury while working with machines that apply the powder coating

- Chemical splashes from manual spray wand systems that are used to clean the medium before powder coating

- Possible damage to lungs and airways resulting from inhalation of the powder coating and other chemicals

- Burns due to accidental combustion of the powder coating media

- Chemical burns and potential eye damage from alkalines and acids in manual spray wand systems, methyl ethyl ketone vapors, and powder coating dust.

Although some powder coating machines have built-in safety mechanisms that eliminate the need for PPE in most circumstances, those who operate the machines and use manual systems for applying powder coat must wear PPE to avoid the potential health risks mentioned above.

The SDS provided for each powder coating used will include associated health risks under the 'Hazard statements' or ‘Risk phrases’.

In particular, look for the following hazards.

- Hazard H302: 'Harmful if swallowed'

- Hazard H317: May cause allergic skin reaction

- Risk R22: 'Harmful if swallowed'

- Risk R43: May cause skin sensitization

High-risk Powder Coating Activities

When applying powder coating, the following activities are known to create the highest airborne dust concentrations:

- Applying powders that contain the toxic materials referenced above (TMA, TGIC, Lead-chromate based pigments)

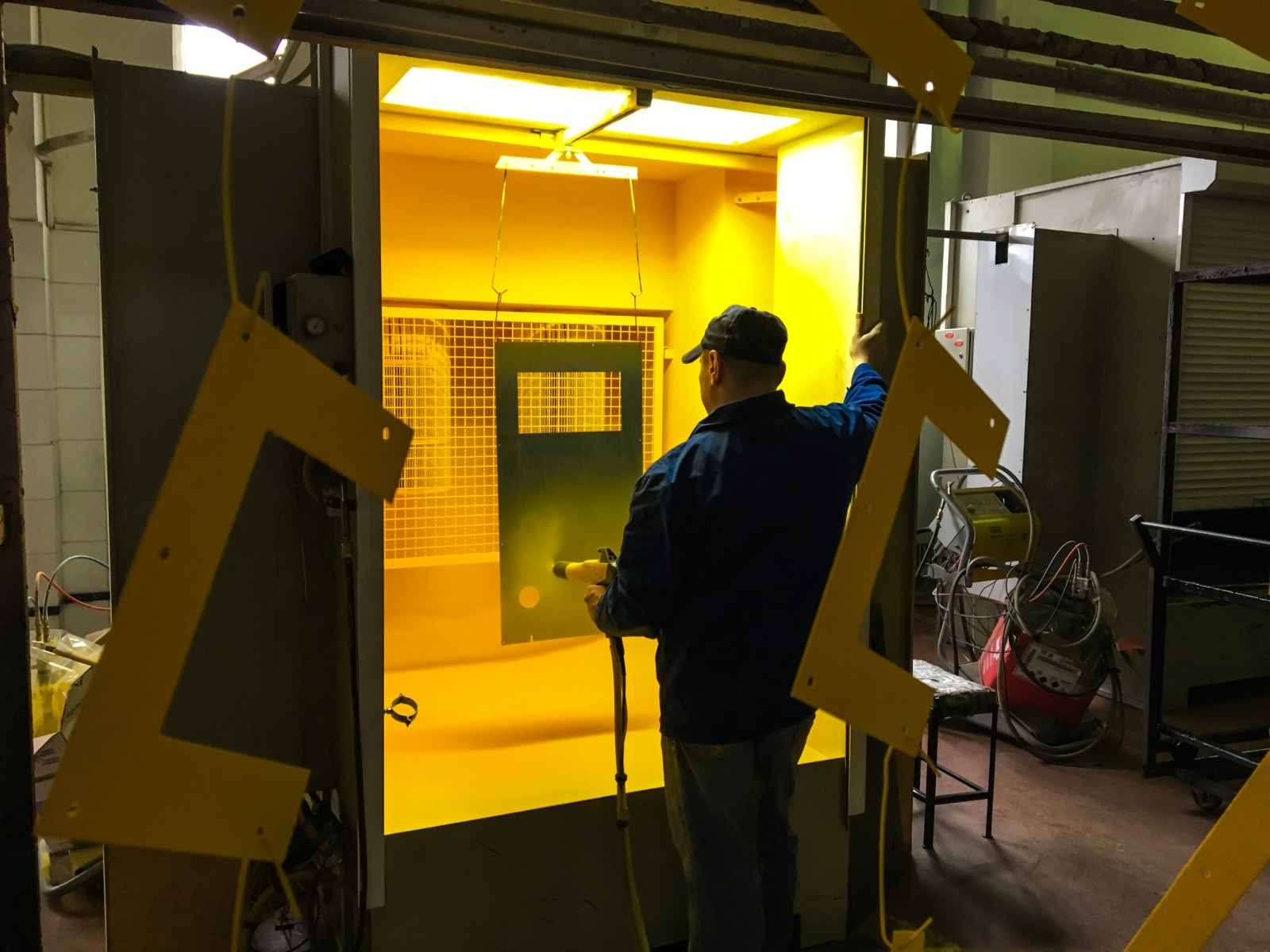

- Spraying powder in powder-coating booths with poor ventilation

- Generating powder transfer throughout maintenance or cleaning

Control measures for Powder Coating

There are numerous risks associated with powder coating, however, there are also many steps businesses can take to control them. You can start reducing risks associated with using coating powders by following safe powder coating guidelines:

- Lowering the temperature reduces the amount of vapor generated

- Enclosing spray booths or designated spray areas to control particle release or escape

- Outline the proper storage and disposal of materials

- Provide designated areas for washing and changing

- Provide appropriate personal protective equipment (PPE)

- Maintain ventilation equipment for functionality, cleanliness, and safety

- Minimize or limit the amount of manual spraying performed; nowadays, many powder coating booths are automatic

- Look for dust on the floor or around openings; this reveals the booth is not running at its top performance

- Keep all doors shut, depending on the task

- Never spray towards another worker operating in tandem or opposite

- Control spray gun settings to limit the amount of powder used to accomplish the needed finish

- Minimize the use of compressed air for cleaning; avoid standing inside the booth to clean it. Use rubber scrapers with long handles and compressed air lances.

For more information, the OSHA standard 29 CFR 1910.107 Spray finishing using flammable and combustible materials applies to aerated solid powders as well as the application of combustible powders by powder spray guns (spray finishing). View all OSHA powder coating regulations.

This regulation outlines airflow requirements, ventilation requirements, paint booth construction materials and location, cleaning, curing equipment, powder-coating equipment requirements, spray finishing operations, and more.

What PPE Do You Need to Wear While Powder Coating?

It's imperative that operators wear properly fitted disposable protective clothing and PPE to ensure their safety. Employees may require the following equipment according to OSHA powder coating PPE requirements, depending on the application and situation. However, a risk assessment should always be performed first to determine which PPE is needed.

- A breathable air supply or full respirator..

- Safety glasses that seal to protect the eyes from particulates.

- Hard hats in areas where there are machines with moving parts.

- Gloves for hand protection.

- A coverall that protects the wearer from noxious particles..

- A suit that protects workers operating automated equipment that may cause splashes .

The type of suit used depends on the risks associated with the task. For example, if you do not operate washers that use unsafe chemicals, it's not likely you need protection from chemical splash.

Choosing the Right Powder Coating Gear for the Right Application Technique

In terms of employee safety, it's critical that they wear PPE. The suggestions below reflect the gear needed at their jobs:

Manual Media Blast Systems

As the name implies, the person enters the spray booth to apply the powder coating to the medium. This worker is at risk of inhaling particulates due to the nature of powder coating. The worker is also at risk of starting a flash fire due to electro-charged particulates and potential sparks resulting from a lack of grounding and faulty equipment. For these situations, we recommend the following PPE:

- A breathable air supply or full respirator.

- Safety glasses and full-face shields that seal to protect the eyes from particulates.

- Heavy gloves to protect hands.

- A suit or coverall that protects the wearer from dangerous or noxious particles.

- A suit that protects the wearer from dangerous flash fires that can occur with combustible dust.

Manual Spray Wand Systems

Manual spray wand systems are used to clean the medium before applying the powder coating. These systems use dangerous chemicals and solvents to clean the object that will be powder coated.

- A coverall to protect workers from hazardous chemical splashes, acids, and/or caustic substances such as ChemSplash® 1 or ChemSplash® 2.

- A safe air supply or full respirator.

- A full-face shield to protect against splashes.

- Heavy gloves to protect the hands.

Automatic Systems

Automatic systems include automated media blast systems, automated washers, and automated powder coating systems. Although these systems usually do not require manual intervention, you still need to protect workers from contaminants, splashes, and potential injury from machinery.

- Safety glasses.

- Hard hats.

- Protective gloves.

- International Enviroguard's MicroGuard MP® and to protect workers from particulates and minor splash.