The debate of wearing disposable flame-resistant clothing (FR or FRC) daily as opposed to only wearing it for specific tasks or “as-needed” is a heated topic. However, when you consider the science and the cold hard facts, there’s a clear winner.

This article covers the top misconceptions of flame-resistant clothing (FRC) and settles the debate between wearing FRC daily or for task-based applications.

The Top 7 Misunderstandings of FR Clothing

1. FR/AR Clothing is Too Hot and will Cause Heat Stress

It is important that workers who utilize FR/AR clothing understand that they are at no greater risk than workers wearing non-FR work clothing. The same precautions (hydration, rest, and shade) help mitigate the effects of wearing layers.

Common Protective Clothing Objections and How to Respond

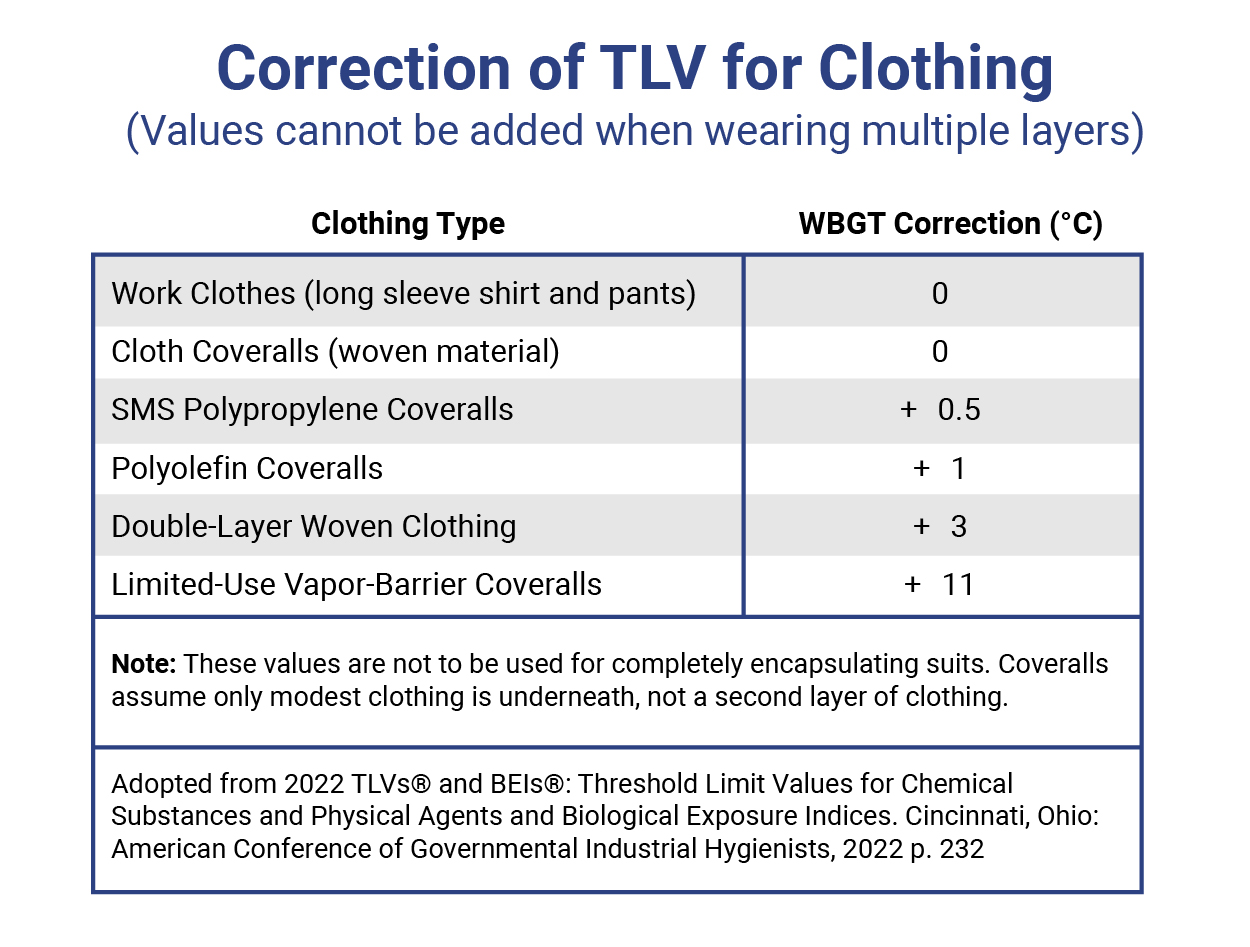

- “It’s introducing more hazards”: FR/AR clothing in a single layer will not cause heat stress. When you look at the heat index CAF (Clothing Adjustment Factor) for single layer coveralls there is no clothing adjustment needed. There is an adjustment when you start layering up in arc flash suits, rain gear, or wearing a disposable FR suit overtop (secondary FR). This does cause a higher risk for heat stress.

The ACGIH TLV for Heat Stress and Strain – it’s important to differentiate the introduction of layering whether in an arc flash suit or safety vests, and even rain gear, the hazard analyses changes:

- It’s too hot, heavy, and uncomfortable: Wear lightweight, air permeable, moisture-wicking coveralls. Many types of PPE actually increase the likelihood of heat exhaustion or heat stroke by trapping heat next to the body and raising a person's internal temperature. To fight this problem, employers should look for clothing with a High Moisture Vapor Transmission Rate or MVTR. Fabric with a high MVTR allows heat and moisture vapor to escape the clothing, so wearers stay cool and maintain a safer internal temperature.

- Lightweight FR is more comfortable: Fabric weight is not an indication of comfort. Moisture management is key. Make sure moisture wicking is a property of the fiber blend and not a finish (all wicking finishes are temporary). Consider looking for fabrics with MVTR and/or moisture-wicking testing.

- It doesn’t fit well: Proper sizing for protective workwear can be tricky—too small of a garment and it will rip and tear when squatting/reaching/bending; too big of a garment and it can get caught in machinery, snag on items, or be in the way. Employers should consider garments that comply with the ANSI/ISEA 105-2016 national standard for limited-use and disposable coveralls.

ANSI helps provide standard specifications and an aspect ratio to maintain consistent sizing across manufacturers who produce protective clothing with ANSI sizing. A table exists that is based on these measurements that are meant to serve as a sizing guide for manufacturers.

Each garment is sized according to a national standard and undergoes wear test requirements to ensure it performs according to its performance class and/or application. Standardization ensures a properly fitting coverall that allows workers to perform tasks without having to adjust, modify, or replace the garment due to ripping or tearing.

2. FR Apparel is Too Expensive

If cost is the primary decision factor in selecting an FR garment, safety is eliminated from the equation. Low-cost FR/AR garments usually come with poor quality and low durability, meaning replacement costs will outweigh initial savings. The real danger of purchasing FR/AR gear solely on price is when your workforce faces the hazards it is intended to mitigate.

FR Gear is Too Expensive - Compared to what?

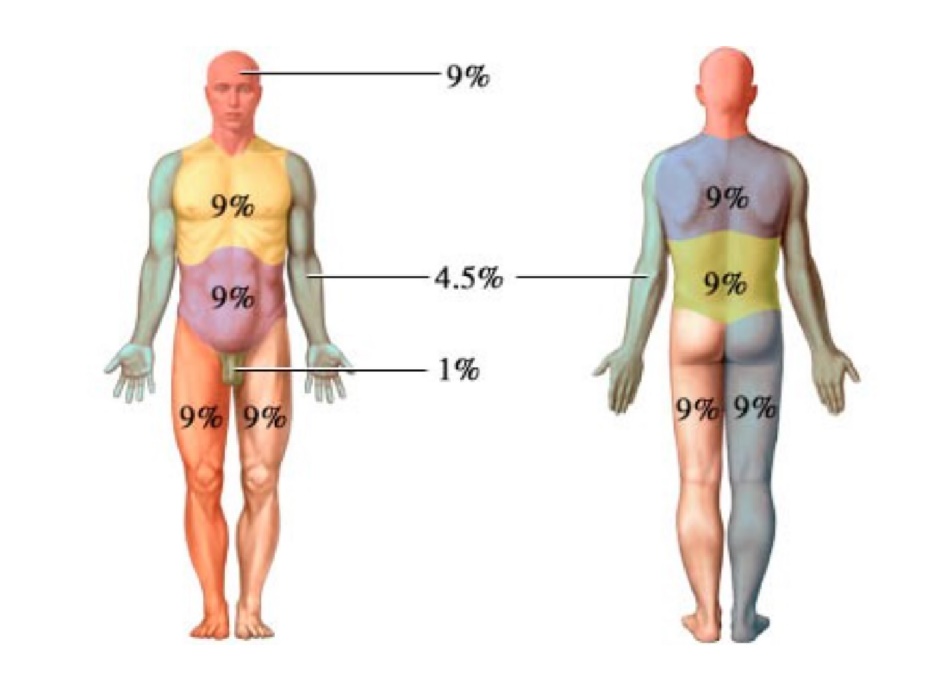

- Burn treatment requires approximately 1.5 days of hospitalization per % of body burn

- The average hospital stay for a survivor with 40-60% body burn is 54 days with costs exceeding $25,000/day

- Hospitalization costs typically range from $200,000 to $75,000 with may costive over $1,000,000 USD.

- Lifetime costs can exceed $10,000,000 USD

3. FR Apparel Doesn’t Really Work

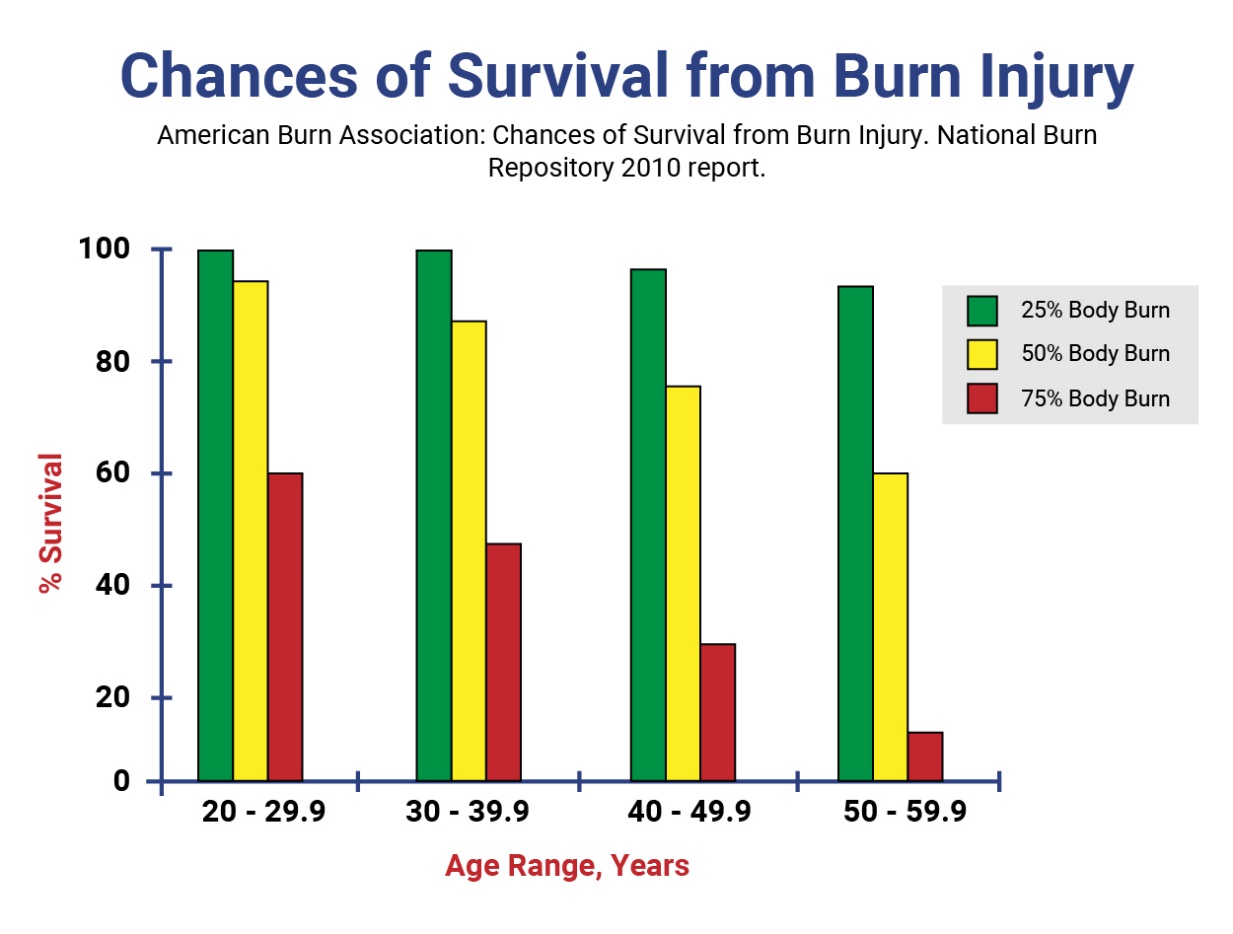

When looking at the data, FR/AR protective clothing clearly works. However, survival rates for all age groups decrease as age increases. This is because the body’s natural ability to heal slows down as we age.

4. It doesn’t matter what I wear underneath my FRC

This is false. Any garment worn as the outer layer, including rainwear, must be FR/AR. Any garment worn as a base layer cannot be made of or contain meltable fibers such as acetate, nylon, polyester, polypropylene, and/or spandex. Only natural fibers such as silk, cotton, or wool are permissible. Base layers are critical. When an FR garment reaches its performance threshold and begins to fail by exposing the non-AR clothing (or skin) underneath, the base layer must be designed to minimize injury. The base layer is closest to the skin, and continued ignition will cause significant body harm.

5. Manikin Test Data tells Which Garment is Best - I want the lowest Body Burn

This is also false. The Manikin Test (ASTM 1930) is not a real-world scenario; it is not designed to be used as a purchase specification. Tests specified to NFPA 2112 should not be deemed as defining or establishing performance levels for protection from all flash fire environments. The test is not done on a commercial “as-sold” garment. The test garment often does not include pockets, additional clothing layers (base layer), zippers, clothing tag, etc. These additional materials or design features can impact how the garment performs in a real-world flash fire event.

6. Inherent FR Fabric is Better than Treated FR Fabric

To better understand this argument, let’s cover the basics. What is the difference between Inherent FR and Treated FR garments?

Inherent FR Fabric refers to fabric that has FR properties naturally. This is defined as the fabric’s ability to self-extinguish when the ignition source is removed. This means that at least one of the fibers used has its own flame-resistant properties. Common examples include modacrylics and aramids. This type of fabric does not have any added finishes or coatings.

- Inherent: includes naturally flame-resistant fibers

- Better performance, especially over time

- How it is laundered doesn’t matter

Treated FR Fabric is typically a cotton-based garment blended with polyester, para-aramid, or polyamide. This blend of fabrics is then treated with a chemical mixture that coats the fibers to provide a flame-resistant finish. This chemical treatment is not permanent and can lose its protective capabilities over time or with frequent or improper washing.

- Chemically dependent

- Surface / topical treatment

- Laundering affects the FR properties

Other considerations include how the FR properties are achieved:

- Molecular level: Synthetic materials are engineered at the molecular level to be flame-resistant.

- Fiber Level: Flame retardant chemicals are added during fiber extrusion (fiber melting and spinning).

- Fabric Level: Fabrics achieve flame resistant properties through chemical and mechanical processes to permanently maintain these FR capabilities.

So, which option is better? The best answer is to decide based on the type of hazards in the work environment and the type of work being done.

7. Task-based vs. Daily wear

Employers commonly outfit their employees with FR/AR coveralls for task-based energized work’; the real question is, are they safe? The simple answer is no. To be complaint, an employer is asking the worker to stop what they are doing and to remember to don their FR/AR coverall.

This is where task-based programs fail, especially if FR/AR clothing has not been part of their safety culture. Remember, energized tasks as defined by NFPA70E include voltage testing, trouble shooting and verifying, and tasks that may be considered routine or “not all that” dangerous by the electrician and thus not require “all that PPE”.

What is wrong with a task-based approach?

Let’s run the numbers: An employer hires 10 electricians and each electrician does an average of 10 energized tasks a day. That equals 100 energized tasks a day, 3,000 energized tasks per month, and over 30,000 opportunities a year for them to not have FR clothing on when they need it.

What about the cost in time to the employer?

- 10 stoppages per day to change in and then out of the FR/AR coverall.

- Cost in time; 5 min to put on the coverall and another 5 min to take it off. This equals 100 min/day/employee.

- 100 min/day times 30 days or 30,000 min a month is equivalent to 500 plus hours a month changing in and out of coveralls.

The Argument for Daily-wear FR/AR clothing

- It provides a baseline of protection at all times—accidents can happen anytime, anywhere.

- It minimizes the time needed to perform daily tasks (changing in and out of garments). This also increases productivity and overall safety levels.

- It minimizes the number of safety-related decisions.

Closing Considerations and Comments

When you consider the science behind FR workwear, it clearly works. When you also consider the benefits of wearing FRC daily, it’s another no-brainer. Flame-resistant workwear has come a long way in terms of effectiveness and comfort. New technology has created more lightweight options that don’t reduce the protective capabilities of the garment. The top three benefits to consider for purchasing FR workwear include lightweight, air permeable, and moisture-wicking fabric. FR workwear with these three features will help improve PPE compliance significantly.