How to Calculate Air Changes Per Hour in a Cleanroom

Maintaining cleanroom air quality is vital in industries like pharmaceuticals, semiconductors, biotechnology, medical device manufacture, and more. One of the key metrics for cleanroom environmental control is Air Changes Per Hour (ACH or ACPH) — the number of times the total volume of air in a room is replaced or “changed” in one hour via filtered supply air (usually HEPA/ULPA).

Getting ACH right ensures particle control, stable temperature/humidity, proper pressure relationships, and clean recovery after disturbances. This article explains how ACH is calculated, what affects the required rate, and what recommendations exist by cleanroom (ISO) class.

What Is Air Changes Per Hour (ACPH / ACH)

In simple terms:

ACH = (Volume of supply air per hour) ÷ (Room volume)

- Room volume = length × width × height (in appropriate units, e.g. cubic meters or cubic feet).

- Supply air per hour generally refers to air that enters through the HEPA/ULPA filters (or whatever high-efficiency filtration the cleanroom uses), not raw ambient air. If recirculation is involved, the effective filtered air flow matters.

When airflow is unidirectional (laminar flow), often in stricter cleanrooms (ISO 5 or better), airflow velocity and ceiling coverage of filters are also used. In less stringent or mixed/unidirectional flow rooms, you can directly compute ACH from volumetric airflow.

Key Factors That Influence How Many Air Changes Are Needed

While ISO classifications provide ballpark ACH ranges, many variables shift what is appropriate. Key influencing factors include:

- Cleanroom ISO Classification / Cleanliness Requirement

The lower the permitted particle count (smaller size, fewer particles), the more ACH needed. ISO-5 and ISO-4 cleanrooms need much higher rates than ISO-8, for example. - Airflow Pattern: Unidirectional vs Non-Unidirectional

- Unidirectional (laminar) flow: supply air flows in a single, uniform direction (often downward), pushing particles out. These rooms tend to require very high ACH or to be measured with airflow velocities rather than just ACH.

- Mixed / non-unidirectional flow: air enters and mixes; return vents may be on walls or ceilings. These need lower ACH than unidirectional for the same class but still need sufficient filtering and sufficient ACH to keep particle levels under control.

- Room Size and Dimensions

Height matters: taller ceilings mean more air volume; making the ceiling lower can reduce required airflow and cost. The shape and layout, such as the presence of alcoves or obstructions, also affect how air moves and how efficiently filtration works. - Occupancy

The number of people in the room at one time. Each person contributes particles via their skin, clothing, and hair, as well as moisture and heat. More occupants → higher ACH required to maintain cleanliness and environmental comfort. - Equipment, Heat Gain, and Processes

Machines may emit particles, heat, and humidity. Processes that use exhaust hoods or produce contaminants must also be accounted for. Heat load impacts HVAC capacity; particle generation from machines or material handling demand more frequent air replacement. - External Conditions, Temperature, & Humidity

Outside air, when used for makeup air, brings in heat, moisture, and possibly airborne contaminants. High outside humidity or temperature extremes increase the HVAC load. Also, if climate control requires tight tolerances, more frequent air changes (or more conditioned/filtered/dehumidified air) helps maintain stability. - Pressure Differentials & Leakage

Cleanrooms often use positive pressure relative to surrounding areas to keep contaminants out. Leakage through doors, seams, airlocks or poor sealing increases contamination risk, which may require higher ACH or more rigorous design in neighboring zones. - Precision / Criticalness of Process

Some processes are extremely sensitive (e.g. semiconductor lithography, vaccine manufacture) and require stricter environmental control for temperature, humidity, and particulates. Those may demand higher ACH and more stringent design of HVAC, filter coverage, and failure redundancy.

How to Calculate ACH: Step-by-Step

Here’s a method cleanroom designers often use:

- Measure room volume: length × width × height.

- Determine the required cleanliness class (the ISO class).

- Select whether the airflow will be unidirectional or mixed.

- Estimate or select the number of occupants, equipment loads, heat gain, and particle generation.

- Choose the filtering strategy—HEPA/ULPA, filter ceiling coverage.

- Compute volumetric airflow needed: multiply room volume by target ACH.

Supply airflow= Room volume x ACH

Make sure the air is filtered to the required efficiency.

- Ensure the HVAC system can handle the temperature, humidity, and pressure requirements plus makeup air or fresh air loads.

- Validate via testing: measure particle counts “at rest” and “in operation,” verify airflow velocity if unidirectional, and test pressure differentials.

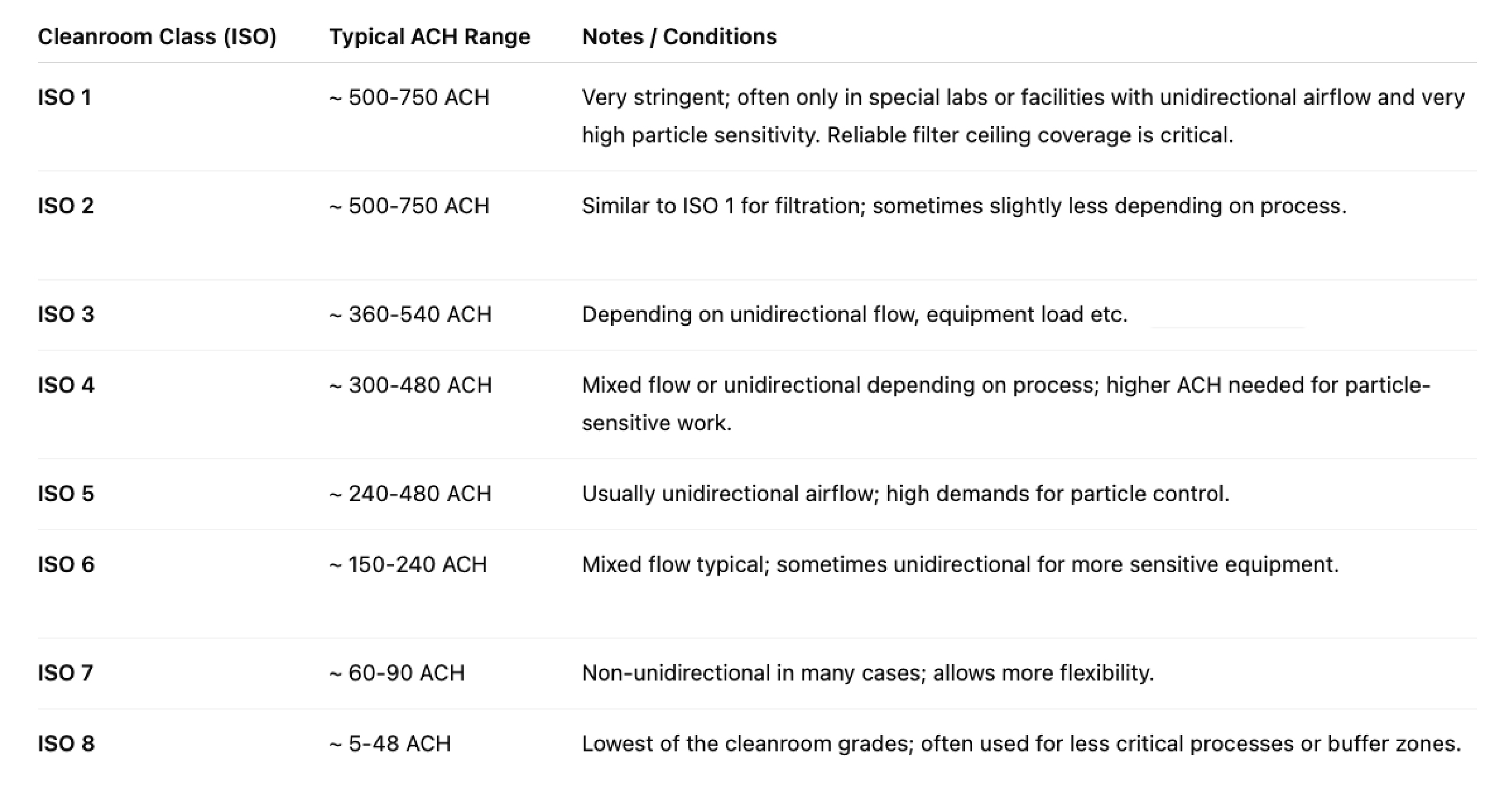

Recommended ACH Ranges by Cleanroom ISO Class

Below are commonly recommended ACH ranges for various ISO cleanroom classes. These ranges are drawn from published guidelines and cleanroom engineering practices. Actual required ACH may vary based on the variables covered above.

Special Cases and Adjustments

- Ante-rooms / Gowning Rooms: These less critical buffer zones may require lower ACH than the main cleanroom but they still need positive pressure and filtration.

- Interdependent rooms: Changing between connected cleanrooms (e.g., ISO 7 → ISO 6) may require airlocks; airflow in adjacent spaces must be considered.

- Operational vs At-Rest: ACH recommendations often assume cleanroom is in operation with people and machines active. Many cleanrooms are allowed to operate at reduced ACH “at rest” to conserve energy, provided environmental stability is maintained and recovery time is acceptable.

- Ceiling coverage of filters: How much of the ceiling is covered with fan filter units matters: higher ceiling coverage helps achieve uniform airflow and better particle control, letting you meet desired cleanliness with lower ACH or a more efficient design.

Example Calculation

Suppose you have an ISO 6 cleanroom, dimensions 10 m long × 8 m wide × 3 m high = 240 m³ volume. Let’s say you choose a target of 200 ACH (within the ISO 6 typical range), and supply airflow is filtered via HEPA filters.

- Airflow required = 240 m³ × 200 ACH = 48,000 m³/hour supply air.

- Confirm that HVAC and fan/filter units can handle 48,000 m³/h with required pressure, temperature, and humidity.

- Account for occupants, machines, and extra extraction. If you have fume hoods or laminar flow benches) — you may need even more supply or additional local exhaust.

Why Precise ACH Matters: Impacts and Trade-offs

- Contamination control & yield: In semiconductor or pharmaceutical manufacturing, small variations in airborne particle loads can ruin batches. Higher ACH reduces particle buildup and accelerates recovery after door openings or personnel movement.

- Environmental and energy cost: HVAC systems consume large portions of energy in cleanrooms. Higher ACH means more conditioning of air (heating/cooling, filtering), which increases cost. Organizations must balance cleanliness vs energy use.

- Comfort and safety: Temperature and humidity control rely on adequate airflow. Insufficient ACH can lead to hot spots, moisture buildup, or discomfort for operators.

- Regulatory compliance: Industries regulated by GMP, ISO 14644, or FDA may require documentation of ACH, cleanroom qualification tests (at rest / operational), etc. Failure to meet ACH can lead to audit failures, batch rejections, or regulatory penalties.

Summary & Best Practices

- Start with the required ISO class for your process. That determines your baseline for cleanliness.

- Choose airflow pattern appropriate to your class: for ISO 5 and cleaner, unidirectional flow is often needed. For ISO 6-8, mixed flow may suffice.

- Calculate room volume precisely, include ceiling height. Factor in occupants, equipment, heat loads, and extraction points.

- Select fan filter unit coverage (ceiling), filter efficiency (HEPA / ULPA), and ensure consistent supply and return air paths.

- Validate design with testing: measure particle counts both “at rest” and under “operational” conditions; airflow uniformity; pressure differentials; recovery times.

- Where possible, allow for reduced ACH “at rest” to save energy, but ensure recovery to class in reasonable time once operations resume.

Conclusion

Calculating air changes per hour is a foundational part of cleanroom design and operations. The right ACH ensures clean, reliable environments that meet critical standards, protect products and people, and support regulatory compliance. But it's not just about cranking up ACH — it’s about balancing multiple variables: room geometry, occupancy, process demands, airflow pattern, filter coverage, energy costs, and operational schedule.

By carefully planning and using best practices, industries can design cleanrooms that maintain the required ISO classification without overspending on energy or infrastructure. If you’re designing or auditing a cleanroom, begin with a clear specification of cleanliness, gather data on room usage and layouts, and engage HVAC and cleanroom engineering experts early.

Sources

“Clean Room Classifications (ISO 8, ISO 7, ISO 6, ISO 5).” Mecart Cleanrooms Learning Center. MECART Cleanrooms

“All About Cleanroom Air Change Rates.” American Cleanrooms. americancleanrooms.com

“Cleanroom Air Change Rates: Requirements and Importance.” Allied Cleanrooms. Allied Cleanrooms

“Cleanroom Air Change Rate Explained.” Connect2Cleanrooms. Connect 2 Cleanrooms