Do you work in an industry that requires FR clothing? FR, or flame resistant, clothing is a type of personal protection equipment (PPE) used to safeguard professionals in more industries than you might initially think. In fact, according to the Occupational Safety and Health Administration (OSHA), professionals should be outfitted with flame resistant PPE in situations where they're exposed to contact with energized circuit panels, electric arcs, molten metal or arcs from faulted conductors, and/or situations where heat energy estimates meet certain criteria. In this post we discuss the many industries that require FR clothing and more importantly, why this PPE is important.

Flame Resistant Clothing Explained

For professionals that work near energized parts or in environments where fuel, vapors, or other combustibles have the potential to linger in the air, there's a greater potential for danger. When it's worn properly, it offers an extra layer of protection from such hazards. In fact, the greatest benefit associated with FR clothing is that it will help to self-extinguish any sort of combustion immediately when it comes into contact with it, thereby meaning that garments won't burn. In addition to protection from combustion, flame resistant PPE also provides enhanced insulation, meaning that even if a garment does combust for a brief period of time, the injury is likely to be minimal. Specifically, this insulation helps prevent the likelihood of severe second and third-degree burns.

Flame resistant clothing can be laundered and reused or purchased in disposable quantities from vendors, including International Enviroguard. Clothing that is reused, however, will need to be properly laundered. Most garment manufacturers outline the proper measures to take in washing this type of clothing, yet there are some universal rules that apply. For instance, bleach or peroxide should never be used. Additionally, arc rated and flame resistant clothing should be washed separate of each other, and always washed inside out to help preserve performance. Liquid detergent is suggested, and the wash cycle should be with cold water, while the dry cycle should be tumble dried. Any garment that needs repair must match the level of protection necessary or it will need to be replaced.

View our range of disposable, fire protective clothing

Arc Rated vs. Flame Resistant PPE

We should note that what was once referred to as "FR clothing" by the National Fire Protection Association (NFPA) is now formally just called "arc rated PPE" or just "AR" per terms of the NFPA 70E Standard, which we'll cover in the forthcoming section.

Why the change? It's because arc rated PPE and FR clothing aren't mutually exclusive. In other words, just because something is designated as FR clothing doesn't also mean that it is arc resistant. FR clothing was deemed to be too general when it came to protection for certain professions, while AR clothing designates a proven degree of protection via testing. For instance, AR clothing is put through what's called a vertical flame test, which essentially measures the performance of the particular article of clothing in a controlled situation.

NFPA Standards

It's worth discussing some of the NFPA standards for proper PPE in the workplace. However, while the following section will include standards that employers are suggested to comply with, it's worth noting that they're just standards. In other words, they have not been accepted as official law yet and are just voluntary or strongly advised.

NFPA 70E

The NFPA 70E is the industry consensus standard for Electrical Safety in the Workplace, a standard that has been endorsed by OSHA for many years when it comes to protection from electric shock and arc flash. It's suggested that anyone who works directly with electrical equipment, as well as those who work near potential hazards, receive NFPA 70E training. While it is not enforceable by law, OSHA often uses the 70E standard as a reference for citations related to other standards involving safety in the workplace. It's worth noting once again that this standard only covers electrical safety.

NFPA 2112

Another standard to know is NFPA 2112, the Standard on Flame Resistant Clothing for Protection of Industrial Personnel Against Short Duration Thermal Exposures from Fire. This standard includes minimum performance requirements that any piece of fire-resistant clothing must meet in order to be considered as such and be worn on a specific worksite. The right PPE is dictated by profession and worksite, and selecting the proper garment is best carried out by matching hazard to regulation.

NFPA 2113

The NFPA 2113 is the standard on the Selection, Care, Use and Maintenance of FR Garments for Protection of Industrial Personnel Against Short-Duration Thermal Exposures from Fire. While the Standard's name is comprehensive enough to be somewhat self-explanatory, it basically helps employers to minimize any safety risks by ensuring that professionals are wearing the appropriate PPE. It also includes details on how this clothing should be worn in the field of work and the proper care and cleaning that should be carried out in maintaining this type of clothing.

ASTM D6413 Vertical Flame Test

As mentioned previously, all AR clothing must undergo a vertical flame test to measure the resistance of garments. This test helps to determine if a garment or fabric will continue to burn after the source of combustion or ignition is removed from the situation. The test helps to measure several things: Afterflame, or the amount of time that a visible flame is present on the fabric; afterglow, or the amount of time where there is a glow on the fabric; and char length, or how much of the fabric has been damaged by the flame. Following the test, fabrics are given a pass/fail grade. Those that pass are adequately determined to meet the NFPA 70E Standard and several OSHA Standards and Policies.

Conditions That Require FR Clothing

FR or AR PPE should be worn by professionals that work near energized parts or in environments where fuel, vapors, or other combustibles have the potential to linger in the air. Per OSHA's General Duty Clause, it's up to employers to assess workplace risk pertaining to fire or electric threats, estimate the potential arc hazards, and provide the proper PPE. Determining the proper PPE is typically carried out via a hazard assessment, where employers assess workplace conditions in an effort to determine the likelihood of various threats. This hazard assessment doesn't just assess workplace hazards, but procedural and environmental ones as well.

Industries That Require FR Clothing

So, what industries and professions require FR and AR rated PPE? There are a lot more than you might initially think. Here's a look at some of the industries and why this type of clothing is important:

Fire Fighting

Firefighters enter hazardous situations on a regular basis and must be properly protected from the elements. Because of the nature of the profession, firefighters typically wear PPE that is highly rated to safeguard them against ignition and insulate them from severe burns. Aside from garments, they also wear facial protection, gloves, and helmets.

Oil and Gas

In the oil and gas industry, workers must be properly protected against flash fires that may occur when exploring for, drilling, refining or working in the field. The NFPA 2112 and 2113 Standards should be the guiding resources for the appropriate PPE in this industry.

Electrical Workers

Electric arcs and arc flashes are common threats that electrical workers face on a daily basis. Wearing self-extinguishing PPE helps reduce the likelihood of severe burns.

General Industry, Construction

From electricians to maintenance workers, arc rated clothing is essential for anyone at potential risk of suffering at least a second-degree burn. While the level of protection required is contingent on the task at hand, professionals in the general trades reinforce the importance of conducting a proper and thorough workplace hazard assessment.

Mining

Mining professionals have the potential to be at risk of combustion, especially in confined environments.

Metal Processing

Any professional who works with heavy industrial equipment on the shop floor should be wearing some level of PPE. From aluminum casing to processing tasks, the potential for injury is present.

Other

There are a variety of other industries that require employees to don the proper PPE, including those who work in producing or packaging fertilizer and other chemicals, plastics, well servicing, wood products and more.

While the Standards and governing bodies that detail recommendations and best practices for FR and AR PPE are important to note, it's equally important to ensure that professionals are wearing the appropriate PPE that will keep them safe and protected should the unthinkable occur on a job site. Employers can either establish an FR clothing rental program or launder reusable PPE themselves.

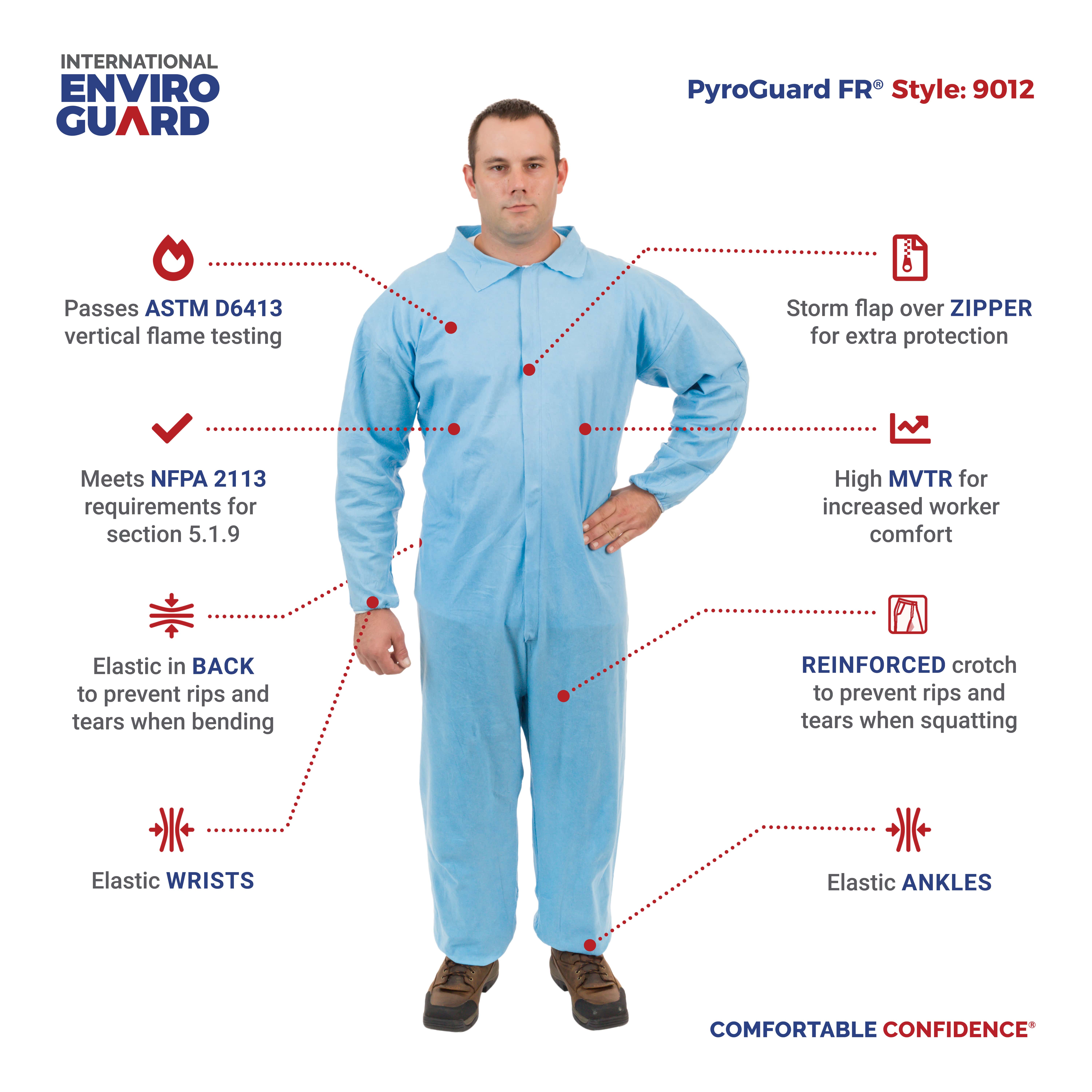

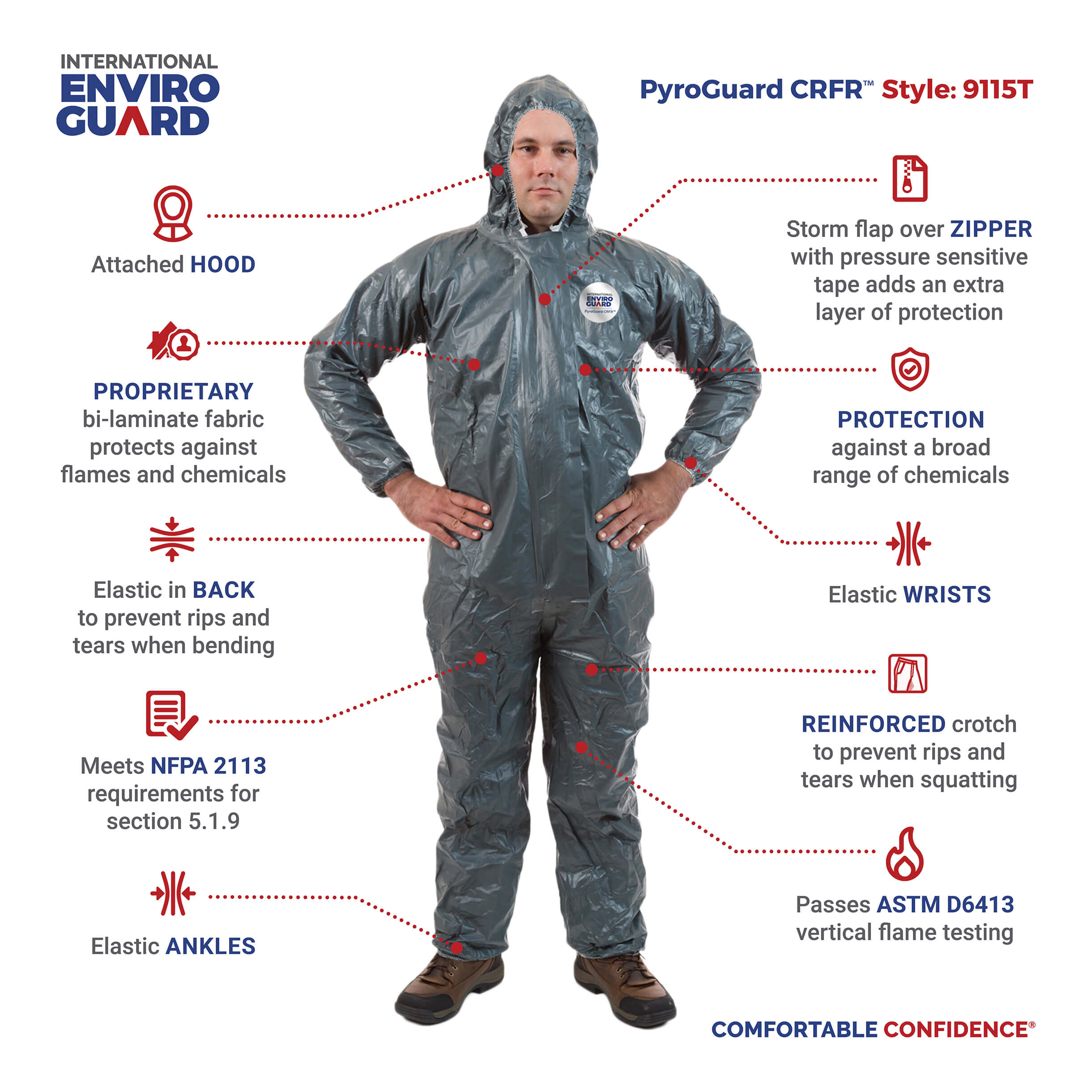

Another option is to purchase disposable FR clothing, such as the PyroGuard options offered by International Enviroguard. These coveralls pass the ASTM D6413 vertical flame test and meet the NFPA's 2113 requirements.

View our full line of PyroGuard products

For more information on FR and AR PPE and to inquire about disposable coveralls, contact International Enviroguard today.