Ammonium hydroxide provides wide-reaching benefits for industries that produce cleaning products, fertilizers, purify water, and others. As the market share and use of this chemical agent grows, an increased number of workers are being put at risk.

Contact with this substance can result in severe burns, damaged vision, and even life-threatening lung conditions. This is why organizations that use ammonium hydroxide should implement safe handling and storage policies that are supported by appropriate ammonium hydroxide PPE.

What is Ammonium Hydroxide?

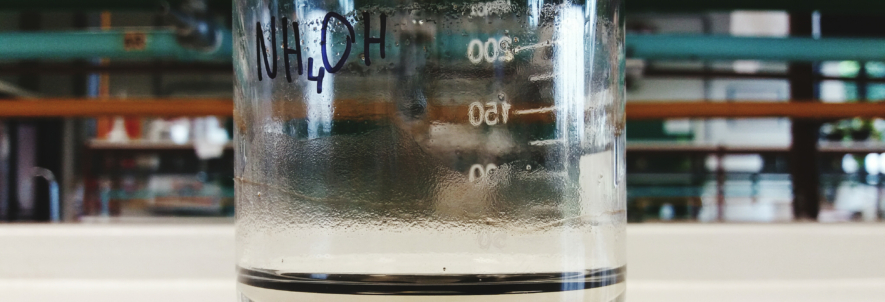

Known by the chemical formula NH₄OH, ammonium hydroxide is a colorless gas with a strong odor that is created by dissolving ammonia in water. Commonly called simply ammonia, ammonia water, or aqueous ammonia, cleaning product manufacturers typically use concentrates of 10 percent in household goods.

When integrated into industrial-grade solutions, concentrations run as high as 30 percent. Although it offers versatility in solutions and applications, the substance poses a serious health risk that calls for the use of ammonium hydroxide PPE and safety measures.

What Industries Commonly Use Ammonium Hydroxide?

The industrial and commercial uses of ammonium hydroxide continue to expand, making it a high-demand product. In the U.S., it saw a market share of $1.4 billion in 2023, and that figure is expected to exceed $2.15 billion by 2032. Primarily used as a cleansing agent, it enjoys broad applications.

- Water Purification: Used in commercial and residential settings as a water purifier and softener, municipalities also use it to support chlorination. An effective disinfectant, it helps reduce health risks associated with waterborne organisms that result from stagnant waters.

- Fertilizer:Considered an essential nitrogen resource in liquid fertilizers, its value stems from its inherently low pH levels, averaging 10 to 11.5. When added to the soil, it helps plants gain access to nutrients.

- Refrigeration:It has applications as a refrigeration gas, largely because it absorbs surrounding heat.

- Laboratory Uses: Ammonium hydroxide acts as a reagent, a solution that helps trigger reactions. In many instances, it helps adjust pH levels.

- Household Cleaning Products:A mainstay in household products, it can be found in both cleanup and sanitizing products as well as window cleaners.

- Industrial Usages: The compound plays an essential role in making fertilizers, plastics, dyes, and textiles.

- Food Additive: It may come as something of a surprise, but ammonium hydroxide has been FDA-approved as a food additive.

- Pharmaceuticals: Prescription drug manufacturers use it as a pH adjuster.

Niche industries such as metal extracting, furniture makers, leather and fur preservation, and semi-conductor manufacturers also use ammonium hydroxide for a wide range of applications.

Its versatility has made it a go-to resource for pH control and sanitization. But those handling ammonium hydroxide are at risk of significant injuries and ailments.

Health Risks Associated with Ammonium Hydroxide

This chemical agent can cause injury or debilitating health conditions from a variety of contact points. When inhaled, ammonium hydroxide generally irritates the lungs. If extended exposure occurs, it can cause fluid to build up in the lungs. Known as a pulmonary edema, this condition constitutes a health emergency.

When workers make physical contact with ammonium hydroxide, it burns the skin and can cause severe damage to the eyes. The substance is also highly toxic to aquatic life and can explode in a fire. These are recommended safety measures to follow if someone suffers from ammonium hydroxide exposure.

- Eye Contact: Promptly flush the eyes with copious amounts of water for a minimum of 30 minutes. Raise the eyelids or find assistance during the flushing process to remove even trace amounts of the substance.

- Skin Contact: When ammonium hydroxide makes skin contact, people often experience a burning sensation. Using soap and lukewarm water, clean and rinse the affected area thoroughly.

- Inhalation:If ammonium hydroxide vapors get into the lungs, it’s crucial to remove yourself and others from the area. Use rescue breathing techniques if necessary and seek medical attention immediately. Keep in mind that pulmonary edema can present upwards of 48 hours after exposure.

The Occupational Safety and Health Administration (OSHA) permissible exposure limit (PEL) restricts ammonium hydroxide to 50 ppm over an 8-hour period. The National Institute for Occupational Safety and Health (NIOSH) calls for a recommended airborne exposure limit (REL) of 25 ppm over 10 hours and no more than 35 ppm within a 15-minute period.

Workplace Controls for Ammonium Hydroxide

Safety mandates that ammonium hydroxide should be stored in a cool, dry space out of direct sunlight. Containers must always have accurate labels that indicate the risk associated with the solution.

Spaces where ammonium hydroxide is stored or handled must be well-ventilated and the workplace should provide fresh or purified air for workers. Ammonium hydroxide is not compatible with acids and chlorine-based products, among others.

It’s generally in the best interest of companies and workers to substitute less harmful chemicals whenever practical. If no viable alternative is available, organizations should implement aqueous ammonia safety measures, such as the following.

- Pass out information highlighting the health and safety risks.

- Monitor airborne particles in the workplace.

- Use appropriate ventilation and controls.

- Have eye-washing stations available for workers.

- Require employees to wash off before breaks and at the end of each shift.

- Do not eat, drink, or smoke in areas containing ammonium hydroxide.

Along with these safe handling recommendations, it’s important for employers to provide a complete inventory of personal protective equipment (PPE) and disposable clothing.

Ammonium Hydroxide PPE Considerations

Under OSHA Personal Protective Equipment Standard 29 CFR 1910.132, employers are tasked with making informed decisions about the best-suited gear and clothing options to prevent workplace accidents, injuries, and health incidents.

Safety administrators should train workers how to use the supplied PPE correctly. They should also demonstrate the donning and doffing procedures surrounding disposable clothing and PPE.

Best practices dictate that workers have a secure location to remove street clothing. After placing the attire in a safe place, they typically proceed to another space to put on PPE and disposable clothing.

When a shift is over, it’s crucial to remove PPE and safety clothing in a designated area, shower or cleanse thoroughly, and proceed to another location to get dressed to leave. Separating these spaces helps reduce the risk of a harmful agent leaving the premises or spreading beyond the doffing area.

These rank among the commonly used ammonium hydroxide PPE.

- Gloves: Splash-resistant gloves should be worn at all times.

- Coveralls: Chemical splash coveralls protect workers from skin burns on their extremities and torso. It’s generally a good idea to use a disposable protective clothing product that offers coveralls with hoods or attachable head protection.

- Eye Protection: Face shields and goggles are considered standard protection in work environments that use harsh and dangerous chemicals.

- Respirators:Industry-leading respirators or breathable masks reduce the inhalation of airborne chemicals and vapors. They are critical in terms of preventing pulmonary edema.

- Footwear Coverings: Shoe or boot covers may be appropriate for occupations that involve handling ammonium hydroxide within certain limits. However, staff members who manage drums and storage may require rubber boots to protect their feet in the event of a chemical spill.